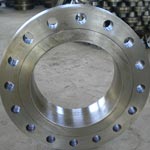

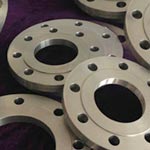

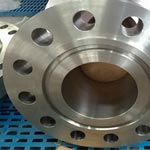

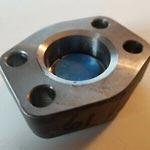

Repute Steel & Engineering Company is a leading manufacturer and supplier of high-quality Socket Weld Flanges in India, catering to high-pressure applications. These flanges are typically used for smaller-sized pipes where precision and strength are critical. A BS-4504 Socket Weld Flange is attached by inserting the pipe into the socket end and securing it with a fillet weld around the top, creating a smooth bore for improved flow of liquids or gases. Available with hub specifications ranging from 1/2" to 24", Socket Weld Reducing Flanges are fabricated according to industry standards such as MSS-SP-44 and ASTM A182, ensuring superior performance and durability across various applications.

At Repute Steel & Engineering Company, we offer Stainless Steel Socket Weld Reducing Flanges and ANSI B16.5 SWRF Flanges, with distributors located in Mumbai, India, serving both domestic and international markets. Our product range includes ASME B16.5 Carbon Steel Socket Weld Flanges in different grades and sizes to meet the specific needs of our clients. Whether it is a raised face (RF), flat face (FF), or Ring Type Joint (RTJ) facing, our flanges adhere to stringent dimensional standards for precise installation. The standard raised face height for SWRF flanges below 400# is 1/16 inch, while for those above 400#, the height increases to 1/4". These flanges are well-suited for demanding environments due to their resistance to corrosion, strength, and ease of maintenance.

Our product portfolio also covers ANSI B16.5 Socket Weld Flanges with pressure ratings from Class 150 to Class 1500 and sizes ranging from NPS 1/2 to NPS 24. The fatigue strength of Carbon Steel Socket Weld Flanges is approximately 50% greater compared to double-welded slip-on flanges, enhancing their reliability for high-pressure systems. We offer custom solutions, including Duplex Steel RTJ Flanges and Socket Weld Flanges A105, fabricated with matching wall thickness dimensions to ensure a perfect fit with the corresponding pipes. These products demonstrate exceptional durability, making them ideal for high-performance piping systems.

Stainless Steel Socket weld Flange material specification chart

| ASME B16.5 Socket weld flanges Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| ASTM A182 SS socket weld blind flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Socket weld Flanges |

| Socket weld raised face flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Socket weld Flanges |

| Socket weld Raised Face Flanges Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Socket weld Flanges, ASME Socket weld Flanges, BS Socket weld Flanges, DIN Socket weld Flanges, EN Socket weld Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| JIS ASME B16.5 SWRF Flanges | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Socket weld Flanges |

| Coating aluminum socket weld flange | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Socket weld Flanges |

| EN socket weld flange a105 | 6Bar 10Bar 16Bar 25Bar 40Bar Socket weld Flanges |

| Connect Type/ Flanges Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| ANSI B16.5 Socket weld Flanges Test | UI trasonic flaw detector, Hydrostatic testing machine, Direct-reading Spectrograph, Magnetic particle detector |

| socket weld ring joint flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

Pressure Class for ASTM A182 SS Socket Weld Blind Flange

| Flanges pressure rating in psig for Socket Weld Flange ASME |

|||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |

Socket Weld Flanges Types

ANSI b16.5 Raised Face Socket Weld Flange

DN65, PN20, SCH40, RF, A182 F316 SW Flange

Socket weld flange Dimensions Class 300

ASME B16.47 Series a Socket Weld Blind Flanges

1500#, MSS SP-44, Stainless Steel SW Flange

MSS SP-44 Socket Weld Hub Flange

EN 1092-1 Ring joint Socket weld Flange

ASME B16.5 Socket Weld Pipe Flange

PN20, DN50, THK SCH 40, Raised Face, A182 F316 SW Flange

ASME B16.5 SWRF Flange

PN50, DN25, THK SCH 40, RF End, A182 F304L Socket Welded Flange

PN16 Socket Weld Flange

ASME B16.47 Series b Flat Face Socket Weld Flanges

SWRF Flanges Dimensions Class 150

Forged Socket Weld Pipe Flange

AWWA C207 Class d Hydraulic Socket Weld Flange

ANSI B16.5 Class 150 Socket Weld Flange Dimensions, 150 lb Socket Weld Flange Dimensions, and 150# Socket Weld Flange Dimensions

|

ANSI, ASME, ASA B16.5 150lb/sq.in. SOCKET WELD FLANGE RF

|

|||||||||||||

|

Nominal Size

|

Outside Diam. | Thick. of Flange | Diam. of Raised Face | Diam of Hub at Base | Length Thru Hub | Diam. of Bore | Depth of Socket | No. of Holes | Diam. of Holes | Approx. Weight Pounds Kg | |||

| O | C | R | X | Y | B | D | |||||||

| 1/2″ | in. | 3.5 | 0.44 | 1.38 | 1.19 | 0.62 | 0.88 | 0.38 | 4 | 0.62 | 1 | ||

| mm. | 88.9 | 11.2 | 35.1 | 30.2 | 15.7 | 22.4 | 9.7 | 15.7 | 0.5 | ||||

| 3/4″ | in. | 3.88 | 0.5 | 1.69 | 1.5 | 0.62 | 1.09 | 0.44 | 4 | 0.62 | 2 | ||

| mm. | 98.6 | 12.7 | 42.9 | 38.1 | 15.7 | 27.7 | 11.2 | 15.7 | 1 | ||||

| 1″ | in. | 4.25 | 0.56 | 2 | 1.94 | 0.69 | 1.36 | 0.5 | 4 | 0.62 | 2 | ||

| mm. | 108 | 14.2 | 50.8 | 49.3 | 17.5 | 34.5 | 12.7 | 15.7 | 1 | ||||

| 1 1/4″ | in. | 4.62 | 0.62 | 2.5 | 2.31 | 0.81 | 1.7 | 0.56 | 4 | 0.62 | 3 | ||

| mm. | 117.3 | 15.7 | 63.5 | 58.7 | 20.6 | 43.2 | 14.2 | 15.7 | 1 | ||||

| 1 1/2″ | in. | 5 | 0.69 | 2.88 | 2.56 | 0.88 | 1.95 | 0.62 | 4 | 0.62 | 3 | ||

| mm. | 127 | 17.5 | 73.2 | 65 | 22.4 | 49.5 | 15.7 | 15.7 | 1 | ||||

| 2″ | in. | 6 | 0.75 | 3.62 | 3.06 | 1 | 2.44 | 0.69 | 4 | 0.75 | 5 | ||

| mm. | 152.4 | 19.1 | 91.9 | 77.7 | 25.4 | 62 | 17.5 | 19.1 | 2 | ||||

| 2 1/2″ | in. | 7 | 0.88 | 4.12 | 3.56 | 1.12 | 2.94 | 0.75 | 4 | 0.75 | 7 | ||

| mm. | 177.8 | 22.4 | 104.6 | 90.4 | 28.4 | 74.7 | 19.1 | 19.1 | 3 | ||||

| 3″ | in. | 7.5 | 0.94 | 5 | 4.25 | 1.19 | 3.57 | 0.81 | 4 | 0.75 | 8 | ||

| mm. | 190.5 | 23.9 | 127 | 108 | 30.2 | 90.7 | 20.6 | 19.1 | 4 | ||||

| 3 1/2″ | in. | 8.5 | 0.94 | 5.5 | 4.81 | 1.25 | 4.07 | 8 | 0.75 | 11 | |||

| mm. | 215.9 | 23.9 | 139.7 | 122.2 | 31.8 | 103.4 | 19.1 | 5 | |||||

| 4″ | in. | 9 | 0.94 | 6.19 | 5.31 | 1.31 | 4.57 | 8 | 0.75 | 13 | |||

| mm. | 228.6 | 23.9 | 157.2 | 134.9 | 33.3 | 116.1 | 19.1 | 6 | |||||

| 5″ | in. | 10 | 0.94 | 7.31 | 6.44 | 1.44 | 5.66 | 8 | 0.88 | 15 | |||

| mm. | 254 | 23.9 | 185.7 | 163.6 | 36.6 | 143.8 | 22.4 | 7 | |||||

| 6″ | in. | 11 | 1 | 8.5 | 7.56 | 1.56 | 6.72 | 8 | 0.88 | 19 | |||

| mm. | 279.4 | 25.4 | 215.9 | 192 | 39.6 | 170.7 | 22.4 | 9 | |||||

| 8″ | in. | 13.5 | 1.12 | 10.62 | 9.69 | 1.75 | 8.72 | 8 | 0.88 | 30 | |||

| mm. | 342.9 | 28.4 | 269.7 | 246.1 | 44.5 | 221.5 | 22.4 | 14 | |||||

| 10″ | in. | 16 | 1.19 | 12.75 | 12 | 1.94 | 10.88 | 12 | 1 | 43 | |||

| mm. | 406.4 | 30.2 | 323.9 | 304.8 | 49.3 | 276.4 | 25.4 | 20 | |||||

| 12″ | in. | 19 | 1.25 | 15 | 14.38 | 2.19 | 12.88 | 12 | 1 | 64 | |||

| mm. | 482.6 | 31.8 | 381 | 365.3 | 55.6 | 327.2 | 25.4 | 29 | |||||

| 14″ | in. | 21 | 1.38 | 16.25 | 15.75 | 2.25 | 14.14 | 12 | 1.12 | 90 | |||

| mm. | 533.4 | 35.1 | 412.8 | 400.1 | 57.2 | 359.2 | 28.4 | 41 | |||||

| 16″ | in. | 23.5 | 1.44 | 18.5 | 18 | 2.5 | 16.16 | 16 | 1.12 | 98 | |||

| mm. | 596.9 | 36.6 | 469.9 | 457.2 | 63.5 | 410.5 | 28.4 | 44 | |||||

| 18″ | in. | 25 | 1.56 | 21 | 19.88 | 2.69 | 18.18 | 16 | 1.25 | 130 | |||

| mm. | 635 | 39.6 | 533.4 | 505 | 68.3 | 461.8 | 31.8 | 59 | |||||

| 20″ | in. | 27.5 | 1.69 | 23 | 22 | 2.88 | 20.2 | 20 | 1.25 | 165 | |||

| mm. | 698.5 | 42.9 | 584.2 | 558.8 | 73.2 | 513.1 | 31.8 | 75 | |||||

| 24″ | in. | 32 | 1.88 | 27.25 | 26.12 | 3.25 | 24.25 | 20 | 1.38 | 220 | |||

| mm. | 812.8 | 47.8 | 692.2 | 663.4 | 82.6 | 616 | 35.1 | 100 | |||||

Class 300 Socket Weld Flange Schedule Dimensions, 300# Socket Weld Flange Dimensions, and Socket Weld Flange Dimensions Class 300

| ANSI, ASME, ASA B16.5 300lb/sq.in. SOCKET WELD FLANGE RF | |||||||||||||

| Nominal Size | Outside Diam. | Thick. of Flange | Diam. of Raised Face | Diam of Hub at Base | Length Thru Hub | Diam. of Bore | Depth of Socket | No. of Holes | Diam. of Holes | Approx. Weight Pounds Kg | |||

| O | C | R | X | Y | B | D | |||||||

| 1/2″ | in. | 3.75 | 0.56 | 1.38 | 1.5 | 0.88 | 0.88 | 0.38 | 4 | 0.62 | 2 | ||

| mm. | 95.3 | 14.2 | 35.1 | 38.1 | 22.4 | 22.4 | 9.7 | 15.7 | 1 | ||||

| 3/4″ | in. | 4.62 | 0.62 | 1.69 | 1.88 | 1 | 1.09 | 0.44 | 4 | 0.75 | 3 | ||

| mm. | 117.3 | 15.7 | 42.9 | 47.8 | 25.4 | 27.7 | 11.2 | 19.1 | 1 | ||||

| 1″ | in. | 4.88 | 0.69 | 2 | 2.12 | 1.06 | 1.36 | 0.5 | 4 | 0.75 | 3 | ||

| mm. | 124 | 17.5 | 50.8 | 53.8 | 26.9 | 34.5 | 12.7 | 19.1 | 1 | ||||

| 1 1/4″ | in. | 5.25 | 0.75 | 2.5 | 2.5 | 1.06 | 1.7 | 0.56 | 4 | 0.75 | 4 | ||

| mm. | 133.4 | 19.1 | 63.5 | 63.5 | 26.9 | 43.2 | 14.2 | 19.1 | 2 | ||||

| 1 1/2″ | in. | 6.12 | 0.81 | 2.88 | 2.75 | 1.19 | 1.95 | 0.62 | 4 | 0.88 | 6 | ||

| mm. | 155.4 | 20.6 | 73.2 | 69.9 | 30.2 | 49.5 | 15.7 | 22.4 | 3 | ||||

| 2″ | in. | 6.5 | 0.88 | 3.62 | 3.31 | 1.31 | 2.44 | 0.69 | 8 | 0.75 | 7 | ||

| mm. | 165.1 | 22.4 | 91.9 | 84.1 | 33.3 | 62 | 17.5 | 19.1 | 3 | ||||

| 2 1/2″ | in. | 7.5 | 1 | 4.12 | 3.94 | 1.5 | 2.94 | 0.75 | 8 | 0.88 | 10 | ||

| mm. | 190.5 | 25.4 | 104.6 | 100.1 | 38.1 | 74.7 | 19.1 | 22.4 | 5 | ||||

| 3″ | in. | 8.25 | 1.12 | 5 | 4.62 | 1.69 | 3.57 | 0.81 | 8 | 0.88 | 13 | ||

| mm. | 209.6 | 28.4 | 127 | 117.3 | 42.9 | 90.7 | 20.6 | 22.4 | 6 | ||||

| 3 1/2″ | in. | 9 | 1.19 | 5.5 | 5.25 | 1.75 | 4.07 | 8 | 0.88 | 17 | |||

| mm. | 228.6 | 30.2 | 139.7 | 133.4 | 44.5 | 103.4 | 22.4 | 8 | |||||

| 4″ | in. | 10 | 1.25 | 6.19 | 5.75 | 1.88 | 4.57 | 8 | 0.88 | 22 | |||

| mm. | 254 | 31.8 | 157.2 | 146.1 | 47.8 | 116.1 | 22.4 | 10 | |||||

| 5″ | in. | 11 | 1.38 | 7.31 | 7 | 2 | 5.66 | 8 | 0.88 | 28 | |||

| mm. | 279.4 | 35.1 | 185.7 | 177.8 | 50.8 | 143.8 | 22.4 | 13 | |||||

| 6″ | in. | 12.5 | 1.44 | 8.5 | 8.12 | 2.06 | 6.72 | 12 | 0.88 | 39 | |||

| mm. | 317.5 | 36.6 | 215.9 | 206.2 | 52.3 | 170.7 | 22.4 | 18 | |||||

| 8″ | in. | 15 | 1.62 | 10.62 | 10.25 | 2.44 | 8.72 | 12 | 1 | 58 | |||

| mm. | 381 | 41.1 | 269.7 | 260.4 | 62 | 221.5 | 25.4 | 26 | |||||

| 10″ | in. | 17.5 | 1.88 | 12.75 | 12.62 | 2.62 | 10.88 | 16 | 1.12 | 81 | |||

| mm. | 444.5 | 47.8 | 323.9 | 320.5 | 66.5 | 276.4 | 28.4 | 37 | |||||

| 12″ | in. | 20.5 | 2 | 15 | 14.75 | 2.88 | 12.88 | 16 | 1.25 | 115 | |||

| mm. | 520.7 | 50.8 | 381 | 374.7 | 73.2 | 327.2 | 31.8 | 52 | |||||

| 14″ | in. | 23 | 2.12 | 16.25 | 16.75 | 3 | 14.14 | 20 | 1.25 | 165 | |||

| mm. | 584.2 | 53.8 | 412.8 | 425.5 | 76.2 | 359.2 | 31.8 | 75 | |||||

| 16″ | in. | 25.5 | 2.25 | 18.5 | 19 | 3.25 | 16.16 | 20 | 1.38 | 190 | |||

| mm. | 647.7 | 57.2 | 469.9 | 482.6 | 82.6 | 410.5 | 35.1 | 86 | |||||

| 18″ | in. | 28 | 2.38 | 21 | 21 | 3.5 | 18.18 | 24 | 1.38 | 250 | |||

| mm. | 711.2 | 60.5 | 533.4 | 533.4 | 88.9 | 461.8 | 35.1 | 113 | |||||

| 20″ | in. | 30.5 | 2.5 | 23 | 23.12 | 3.75 | 20.2 | 24 | 1.38 | 315 | |||

| mm. | 774.7 | 63.5 | 584.2 | 587.2 | 95.3 | 513.1 | 35.1 | 143 | |||||

| 24″ | in. | 36 | 2.75 | 27.25 | 27.62 | 4.19 | 24.25 | 24 | 1.62 | 475 | |||

| mm. | 914.4 | 69.9 | 692.2 | 701.5 | 106.4 | 616 | 41.1 | 215 | |||||

Class 600 Socket Weld Flange Standard Dimensions, 600# Socket Weld Flange Dimensions & 600 lb Socket Weld Flange Dimensions

|

ANSI, ASME, ASA B16.5 600lb/sq.in. SOCKET WELD FLANGE

|

|||||||||||||

| Nominal Size | Outside Diam. | Thick. of Flange | Diam. of Raised Face | Diam of Hub at Base | Length Thru Hub | Diam. of Bore | Depth of Socket | No. of Holes | Diam. of Holes | Approx. Weight Pounds Kg | |||

| O | C | R | X | Y | B | D | |||||||

| 1/2″ | in. | 3.75 | 0.56 | 1.38 | 1.5 | 0.88 | 0.88 | 0.38 | 4 | 0.62 | 2 | ||

| mm. | 95.3 | 14.2 | 35.1 | 38.1 | 22.4 | 22.4 | 9.7 | 15.7 | 1 | ||||

| 3/4″ | in. | 4.62 | 0.62 | 1.69 | 1.88 | 1 | 1.09 | 0.44 | 4 | 0.75 | 3 | ||

| mm. | 117.3 | 15.7 | 42.9 | 47.8 | 25.4 | 27.7 | 11.2 | 19.1 | 1 | ||||

| 1″ | in. | 4.88 | 0.69 | 2 | 2.12 | 1.06 | 1.36 | 0.5 | 4 | 0.75 | 4 | ||

| mm. | 124 | 17.5 | 50.8 | 53.8 | 26.9 | 34.5 | 12.7 | 19.1 | 2 | ||||

| 1 1/4″ | in. | 5.25 | 0.81 | 2.5 | 2.5 | 1.12 | 1.7 | 0.56 | 4 | 0.75 | 5 | ||

| mm. | 133.4 | 20.6 | 63.5 | 63.5 | 28.4 | 43.2 | 14.2 | 19.1 | 2 | ||||

| 1 1/2″ | in. | 6.12 | 0.88 | 2.88 | 2.75 | 1.25 | 1.95 | 0.62 | 4 | 0.88 | 7 | ||

| mm. | 155.4 | 22.4 | 73.2 | 69.9 | 31.8 | 49.5 | 15.7 | 22.4 | 3 | ||||

| 2″ | in. | 6.5 | 1 | 3.62 | 3.31 | 1.44 | 2.44 | 0.69 | 8 | 0.75 | 9 | ||

| mm. | 165.1 | 25.4 | 91.9 | 84.1 | 36.6 | 62 | 17.5 | 19.1 | 4 | ||||

| 2 1/2″ | in. | 7.5 | 1.12 | 4.12 | 3.94 | 1.62 | 2.94 | 0.75 | 8 | 0.88 | 13 | ||

| mm. | 190.5 | 28.4 | 104.6 | 100.1 | 41.1 | 74.7 | 19.1 | 22.4 | 6 | ||||

| 3″ | in. | 8.25 | 1.25 | 5 | 4.62 | 1.81 | 3.57 | 0.81 | 8 | 0.88 | 16 | ||

| mm. | 209.6 | 31.8 | 127 | 117.3 | 46 | 90.7 | 20.6 | 22.4 | 7 | ||||

| 3 1/2″ | in. | 9 | 1.38 | 5.5 | 5.25 | 1.94 | 4.07 | 8 | 1 | 21 | |||

| mm. | 228.6 | 35.1 | 139.7 | 133.4 | 49.3 | 103.4 | 25.4 | 10 | |||||

| 4″ | in. | 10.75 | 1.5 | 6.19 | 6 | 2.12 | 4.57 | 8 | 1 | 37 | |||

| mm. | 273.1 | 38.1 | 157.2 | 152.4 | 53.8 | 116.1 | 25.4 | 17 | |||||

| 5″ | in. | 13 | 1.75 | 7.31 | 7.44 | 2.38 | 5.66 | 8 | 1.12 | 63 | |||

| mm. | 330.2 | 44.5 | 185.7 | 189 | 60.5 | 143.8 | 28.4 | 29 | |||||

| 6″ | in. | 14 | 1.88 | 8.5 | 8.75 | 2.62 | 6.72 | 12 | 1.12 | 80 | |||

| mm. | 355.6 | 47.8 | 215.9 | 222.3 | 66.5 | 170.7 | 28.4 | 36 | |||||

| 8″ | in. | 16.5 | 2.19 | 10.62 | 10.75 | 3 | 8.72 | 12 | 1.25 | 115 | |||

| mm. | 419.1 | 55.6 | 269.7 | 273.1 | 76.2 | 221.5 | 31.8 | 52 | |||||

| 10″ | in. | 20 | 2.5 | 12.75 | 13.5 | 3.38 | 10.88 | 16 | 1.38 | 170 | |||

| mm. | 508 | 63.5 | 323.9 | 342.9 | 85.9 | 276.4 | 35.1 | 77 | |||||

| 12″ | in. | 22 | 2.62 | 15 | 15.75 | 3.62 | 12.88 | 20 | 1.38 | 200 | |||

| mm. | 558.8 | 66.5 | 381 | 400.1 | 91.9 | 327.2 | 35.1 | 91 | |||||

| 14″ | in. | 23.75 | 2.75 | 16.25 | 17 | 3.69 | 14.14 | 20 | 1.5 | 230 | |||

| mm. | 603.3 | 69.9 | 412.8 | 431.8 | 93.7 | 359.2 | 38.1 | 104 | |||||

| 16″ | in. | 27 | 3 | 18.5 | 19.5 | 4.19 | 16.16 | 20 | 1.62 | 330 | |||

| mm. | 685.8 | 76.2 | 469.9 | 495.3 | 106.4 | 410.5 | 41.1 | 150 | |||||

| 18″ | in. | 29.25 | 3.25 | 21 | 21.5 | 4.62 | 18.18 | 20 | 1.75 | 400 | |||

| mm. | 743 | 82.6 | 533.4 | 546.1 | 117.3 | 461.8 | 44.5 | 181 | |||||

| 20″ | in. | 32 | 3.5 | 23 | 24 | 5 | 20.2 | 24 | 1.75 | 510 | |||

| mm. | 812.8 | 88.9 | 584.2 | 609.6 | 127 | 513.1 | 44.5 | 231 | |||||

| 24″ | in. | 37 | 4 | 27.25 | 28.25 | 5.5 | 24.25 | 24 | 2 | 730 | |||

| mm. | 939.8 | 101.6 | 692.2 | 717.6 | 139.7 | 616 | 50.8 | 331 | |||||

Socket Weld Flange Weight Table

ANSI, ASME, ASA B16.5 150lb/sq.in. SOCKET WELD FLANGE RF

|

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal Size | Outside Diam. | Thick. of Flanges | Diam. of Raised Face | Diam of Hub at Base | Length Thru Hub | Diam. of Bore | Depth of Socket | No. of Holes | Diam. of Holes | Diam. of Bolts | Diam. of Bolt Circle | Approx. Weight Pounds Kg | |

| O | C | R | X | Y | B | D | |||||||

| 1/2" | in. | 3.5 | 0.44 | 1.38 | 1.19 | 0.62 | 0.88 | 0.38 | 4 | 0.62 | 1/2 | 2.38 | 1 |

| mm. | 88.9 | 11.2 | 35.1 | 30.2 | 15.7 | 22.4 | 9.7 | 15.7 | 12.7 | 60.5 | 0.5 | ||

| 3/4" | in. | 3.88 | 0.5 | 1.69 | 1.5 | 0.62 | 1.09 | 0.44 | 4 | 0.62 | 1/2 | 2.75 | 2 |

| mm. | 98.6 | 12.7 | 42.9 | 38.1 | 15.7 | 27.7 | 11.2 | 15.7 | 12.7 | 69.9 | 1 | ||

| 1" | in. | 4.25 | 0.56 | 2 | 1.94 | 0.69 | 1.36 | 0.5 | 4 | 0.62 | 1/2 | 3.12 | 2 |

| mm. | 108 | 14.2 | 50.8 | 49.3 | 17.5 | 34.5 | 12.7 | 15.7 | 12.7 | 79.2 | 1 | ||

| 1 1/4" | in. | 4.62 | 0.62 | 2.5 | 2.31 | 0.81 | 1.7 | 0.56 | 4 | 0.62 | 1/2 | 3.5 | 3 |

| mm. | 117.3 | 15.7 | 63.5 | 58.7 | 20.6 | 43.2 | 14.2 | 15.7 | 12.7 | 88.9 | 1 | ||

| 1 1/2" | in. | 5 | 0.69 | 2.88 | 2.56 | 0.88 | 1.95 | 0.62 | 4 | 0.62 | 1/2 | 3.88 | 3 |

| mm. | 127 | 17.5 | 73.2 | 65 | 22.4 | 49.5 | 15.7 | 15.7 | 12.7 | 98.6 | 1 | ||

| 2" | in. | 6 | 0.75 | 3.62 | 3.06 | 1 | 2.44 | 0.69 | 4 | 0.75 | 5/8 | 4.75 | 5 |

| mm. | 152.4 | 19.1 | 91.9 | 77.7 | 25.4 | 62 | 17.5 | 19.1 | 15.9 | 120.7 | 2 | ||

| 2 1/2" | in. | 7 | 0.88 | 4.12 | 3.56 | 1.12 | 2.94 | 0.75 | 4 | 0.75 | 5/8 | 5.5 | 7 |

| mm. | 177.8 | 22.4 | 104.6 | 90.4 | 28.4 | 74.7 | 19.1 | 19.1 | 15.9 | 139.7 | 3 | ||

| 3" | in. | 7.5 | 0.94 | 5 | 4.25 | 1.19 | 3.57 | 0.81 | 4 | 0.75 | 5/8 | 6 | 8 |

| mm. | 190.5 | 23.9 | 127 | 108 | 30.2 | 90.7 | 20.6 | 19.1 | 15.9 | 152.4 | 4 | ||

| 3 1/2" | in. | 8.5 | 0.94 | 5.5 | 4.81 | 1.25 | 4.07 | 8 | 0.75 | 5/8 | 7 | 11 | |

| mm. | 215.9 | 23.9 | 139.7 | 122.2 | 31.8 | 103.4 | 19.1 | 15.9 | 177.8 | 5 | |||

| 4" | in. | 9 | 0.94 | 6.19 | 5.31 | 1.31 | 4.57 | 8 | 0.75 | 5/8 | 7.5 | 13 | |

| mm. | 228.6 | 23.9 | 157.2 | 134.9 | 33.3 | 116.1 | 19.1 | 15.9 | 190.5 | 6 | |||

| 5" | in. | 10 | 0.94 | 7.31 | 6.44 | 1.44 | 5.66 | 8 | 0.88 | 3/4 | 8.5 | 15 | |

| mm. | 254 | 23.9 | 185.7 | 163.6 | 36.6 | 143.8 | 22.4 | 19.1 | 215.9 | 7 | |||

| 6" | in. | 11 | 1 | 8.5 | 7.56 | 1.56 | 6.72 | 8 | 0.88 | 3/4 | 9.5 | 19 | |

| mm. | 279.4 | 25.4 | 215.9 | 192 | 39.6 | 170.7 | 22.4 | 19.1 | 241.3 | 9 | |||

| 8" | in. | 13.5 | 1.12 | 10.62 | 9.69 | 1.75 | 8.72 | 8 | 0.88 | 3/4 | 11.75 | 30 | |

| mm. | 342.9 | 28.4 | 269.7 | 246.1 | 44.5 | 221.5 | 22.4 | 19.1 | 298.5 | 14 | |||

| 10" | in. | 16 | 1.19 | 12.75 | 12 | 1.94 | 10.88 | 12 | 1 | 7/8 | 14.25 | 43 | |

| mm. | 406.4 | 30.2 | 323.9 | 304.8 | 49.3 | 276.4 | 25.4 | 22.2 | 362 | 20 | |||

| 12" | in. | 19 | 1.25 | 15 | 14.38 | 2.19 | 12.88 | 12 | 1 | 7/8 | 17 | 64 | |

| mm. | 482.6 | 31.8 | 381 | 365.3 | 55.6 | 327.2 | 25.4 | 22.2 | 431.8 | 29 | |||

| 14" | in. | 21 | 1.38 | 16.25 | 15.75 | 2.25 | 14.14 | 12 | 1.12 | 1 | 18.75 | 90 | |

| mm. | 533.4 | 35.1 | 412.8 | 400.1 | 57.2 | 359.2 | 28.4 | 25.4 | 476.3 | 41 | |||

| 16" | in. | 23.5 | 1.44 | 18.5 | 18 | 2.5 | 16.16 | 16 | 1.12 | 1 | 21.25 | 98 | |

| mm. | 596.9 | 36.6 | 469.9 | 457.2 | 63.5 | 410.5 | 28.4 | 25.4 | 539.8 | 44 | |||

| 18" | in. | 25 | 1.56 | 21 | 19.88 | 2.69 | 18.18 | 16 | 1.25 | 1 1/8 | 22.75 | 130 | |

| mm. | 635 | 39.6 | 533.4 | 505 | 68.3 | 461.8 | 31.8 | 28.6 | 577.9 | 59 | |||

| 20" | in. | 27.5 | 1.69 | 23 | 22 | 2.88 | 20.2 | 20 | 1.25 | 1 1/8 | 25 | 165 | |

| mm. | 698.5 | 42.9 | 584.2 | 558.8 | 73.2 | 513.1 | 31.8 | 28.6 | 635 | 75 | |||

| 24" | in. | 32 | 1.88 | 27.25 | 26.12 | 3.25 | 24.25 | 20 | 1.38 | 1 1/4 | 29.5 | 220 | |

| mm. | 812.8 | 47.8 | 692.2 | 663.4 | 82.6 | 616 | 35.1 | 31.8 | 749.3 | 100 | |||

JIS B2220 10K Socket Weld Flange Dimensions, JIS 5K Blind Flange Dimensions

| Nominal Size | Outside diameter of flange | Diameter of bolt hole centre circle | Diamter of bolt hole | Number of bolt | Nominal desig-nation of thread of bolt |

Inside diameter | Inside diameter | Depth of socket | Thickness of Flange | Diameter of hub Small diameter side | Diameter of hub Large diamter side | Totle length of flange | Radius of fillet |

| A | D | C | h | d0 | d(18) | S | t | a | b | T | r | ||

| 10 15 20 |

90 95 100 |

65 70 75 |

15 15 15 |

4 4 4 |

M12 M12 M12 |

17.8 22.2 27.7 |

12.7 16.1 21.6 |

10 10 13 |

12 12 14 |

23 27 33 |

26 30 36 |

16 16 20 |

4 4 4 |

| 25 32 40 |

125 135 140 |

90 100 105 |

19 19 19 |

4 4 4 |

M16 M16 M16 |

34.5 43.2 49.1 |

27.6 35.7 41.6 |

13 13 13 |

14 16 16 |

41 50 56 |

44 53 60 |

20 22 24 |

4 4 4 |

| 50 65 80 |

155 175 185 |

120 140 150 |

19 19 19 |

4 4 8 |

M16 M16 M16 |

61.1 77.1 90.0 |

52.9 67.9 80.7 |

16 16 16 |

16 18 18 |

69 86 99 |

73 91 105 |

24 27 30 |

4 4 4 |