Repute Steel & Engineering Company is leading manufacturer of Buttweld Fittings and supply high-quality ANSI / ASME b16.9 Butt weld Split Tees offer you the best prices in the market. These are widely used in industries like oil, gas, shipping, petroleum, and food etc. These are available in different sizes, grades & Specifications in clients requirement. We offer these products at most competitive prices. Carbon Steel, Alloy Steel ASME B16.25, ANSI B19.28, MSS-SP-43 Pipe Split Tee, Split Tee Manufacturer & Exporter

Split neck tee Spec chart

| Specifications | ASME B16.9 Split tee |

|---|---|

| Split tee joint Thickness | SCH30, STD SCH40, SCH10, SCH20, SCH60, XS, SCH 100, SCH 80, SCH 160, SCH 140, SCH 120, XXS available with NACE MR 01-75 |

| Split tee pipe fitting Dimensions | ASME/ ANSI B16.9, ASME B16.28, MSS-SP-43, BS1560, BS4504, BS4504, BS10 |

| Carbon Steel Split Tee Size Range | ½ inch NB to 24 inch NB in schedules like Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| Split weld tee Pipe Fittings size | Seamless Butt Weld Fittings range: 1/2" - 10", Welded ButtWeld Fittings range: 1/2" - 48" |

| Split tee pipe fitting Fittings | Angle : 30deg, 22.5 degree, 45 deg, 180 degree, 90 deg, 2.0D, 1.0D, 1.5D, 4D, 5D, 2.5D, 3D, 6D, 7D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Stainless Steel Split Tee Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Application Industries |

|

| Origin & Mills | Japanese, Indian, European, USA, Ukraine |

Cost of Split back tee

| ASME B16.9 Split tee Type | Stainless Steel Split tee Price in India | Carbon Steel Split tee Price in Saudi Riyal | ASME B16.9 Split tee Price in UAE Dirham |

|---|---|---|---|

| ASTM A234 WPB barred | INR 669.84 | SAR 35.25 | AED 34.54 |

| XB 3 Way ASME B16.9 Steel Equal Pipe | INR 883.62 | SAR 46.50 | AED 45.56 |

| ASTM A234 wpb 8 inch carbon steel pipe | INR 1083.15 | SAR 57.00 | AED 55.85 |

| T- pipe fittings steel pipe split Reducing tee | INR 1410.95 | SAR 74.25 | AED 72.75 |

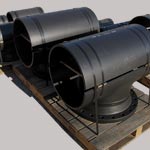

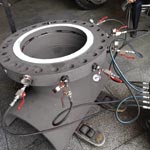

Various types of Split equal tee

ASME B16.9 Split tee SCH 10

ANSI B16.9 Split weld tee Sch 80

Alloy Steel split tee fitting

ASME B16.9 SS split tee welding

ASME B16.9 split neck tee sch 40

Buttweld split tee material

DIN 28011 Pipe Split tee

ASTM A234 WP5 split back tee

A403 Gr WP304 Seamless split weld tee

MSS SP43 SS split equal tee

A403 Grade WP316 SS split long tee

Carbon Steel split tee pipe fitting

A234 Gr WPB CS split front tee

Stainless Steel split sleeve tee

ANSI B16.9 reducing split tee

SA234 WP11 piping split tee

Lap Joint Stub End Dimensions

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Long Pattern | Short Pattern | Radius of Fillet | Diameter of Lap | |

|---|---|---|---|---|---|---|

| Max | Min | F | F | R | G | |

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1-1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1-1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2-1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3-1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| 14 | 359.5 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462 | 456 | 305 | 152 | 13 | 533 |

| 20 | 514 | 507 | 305 | 152 | 13 | 584 |

| 22 | 565 | 558 | 305 | 152 | 13 | 641 |

| 24 | 616 | 609 | 305 | 152 | 13 | 692 |

Stub End MSS SP 43 Dimensions

|

STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension |

|||||||

|---|---|---|---|---|---|---|---|

| inches | ND | mm | Diameter of lap |

Radius of fillet |

Length F | ||

|

D |

G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

Weight Chart Of pipe stub end

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

Stub Ends Length

Facing: 125-250 RMS (smooth finish)

welded version = w

= s seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 “ | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 “ | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 “ | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 “ | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 “ | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |