MANUFACTURER/EXPORTER IN INDIA | ASME/ANSI B16.9, ANSI B16.28,

MSS-SP-43

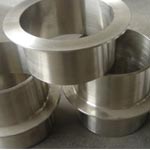

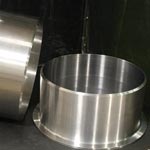

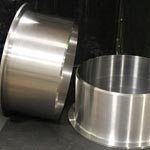

CARBON, ALLOY, STAINLESS STEEL LONG/SHORT PATTERN STUB ENDS

Repute Steel & Engineering Company is ISO 9001:2008 certified company and one of the Largest

manufacturer, exporter and supplier of high quality, high-performance stub end fittings in

all major grades and dimensions. Stub ends can be supplied in standard and non-standard ANSI

dimensions. Repute Steel & Engineering Company offers ex-stock supply of stainless steel

stub ends, carbon steel stub ends, alloy steel stub ends and nickel alloy stub ends. Special

length stub ends can also be offered on demand.

Stub ends are fittings used in place of welded flanges where rotating back up flanges are

desired. They are mainly used with standard Lap Joint Flanges.

We manufacture and supply stub ends in various grades such as 304/304L, 304H, 316/316L, 321,

347, Duplex steel, 904L, Alloy 20, 317L and 310S. We supply stainless steel stub ends across

various industry verticals such as power generation, oil and gas, petrochemical, chemical,

fabrication and engineering, waste water treatment, and pharmaceutical industry.

Specification of Lap Joint Stub End

| Specifications | ASME B16.9 Stub End |

|---|---|

| welded stub end Pipe Fittings size | Seamless Butt Weld Fittings: 1/2" - 10" Welded Butt Weld Fittings: 1/2" - 48" |

| type a stub end Dimensions | ASME/ANSI B16.9, ASME B16.28, MSS-SP-43, BS4504, BS4504, BS1560, BS10 |

| pipe stub end Thickness | SCH10, SCH20, SCH30, STD SCH40, SCH60, XS, SCH 80, SCH 100, SCH 120, SCH 140, SCH 160, XXS available with NACE MR 01-75 |

| schedule 80 stub end Types | Seamless / ERW / Welded / Fabricated Pipe Fittings |

| sch 10 stub end Type | DN15-DN1200 |

| Connection | Welding |

| Bending Radius | R=1D, 2D, 3D, 5D, 6D, 8D, 10D or Custom Pipe Fittings |

| Stub End Buttweld Fittings Size Range | ½" NB to 24" NB in Sch 10s, 40s, 80s, 160s, XXS. (DN6~DN100) |

| type a stub end Fittings | Angle : 22.5 deg, 30deg, 45 deg, 90 deg, 180 deg, 1.0D, 1.5D, 2.0D, 2.5D,

3D, 4D, 5D, 6D, 7D-40D. Standard: ASME B16.9, ASME B16.28, ASME B16.25, MSS SP-75 DIN2605 JISB2311 JISB2312 JISB2313, BS, GB, ISO |

| Manufacturing process | Push, Press, Forge, Cast, etc. |

| schedule 80 stub end Fittings Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Origin & Mills | Japanese, Indian, USA, Korean, European, Ukraine, Russian |

| Key markets and industries for Stub End |

|

| Application |

|

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Material of Stub End

Dimensions of type a stub end

| Nominal Pipe Size | Outside diameter of barrel |

Length (F) | Radius (R) | Diameter (G) | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Long Pattern |

Short Pattern |

|||

| 1/2″ | 20.5 | 22.8 | 76 | 51 | 3 | 35 |

| 3/4″ | 25.9 | 28.1 | 76 | 51 | 3 | 43 |

| 1″ | 32.6 | 35.0 | 102 | 51 | 3 | 51 |

| 1 1/4″ | 41.4 | 43.6 | 102 | 51 | 5 | 64 |

| 1 1/2″ | 47.5 | 49.9 | 102 | 51 | 6 | 74 |

| 2″ | 59.5 | 62.4 | 152 | 64 | 8 | 92 |

| 2 1/2″ | 72.2 | 75.3 | 152 | 64 | 8 | 105 |

| 3″ | 88.1 | 91.3 | 152 | 64 | 10 | 127 |

| 3 1/2″ | 100.8 | 104.0 | 152 | 76 | 10 | 140 |

| 4″ | 113.5 | 116.7 | 152 | 76 | 11 | 157 |

| 5″ | 140.5 | 144.3 | 203 | 76 | 11 | 186 |

| 6″ | 167.5 | 171.3 | 203 | 89 | 13 | 216 |

| 8″ | 218.3 | 222.1 | 203 | 102 | 13 | 270 |

| 10″ | 272.3 | 277.2 | 254 | 127 | 13 | 324 |

| 12″ | 323.1 | 328.0 | 254 | 152 | 13 | 381 |

| 14″ | 354.8 | 359.9 | 305 | 152 | 13 | 413 |

| 16″ | 405.6 | 411.0 | 305 | 152 | 13 | 470 |

| 18″ | 456.0 | 462.0 | 305 | 152 | 13 | 533 |

| 20″ | 507.0 | 514.0 | 305 | 152 | 13 | 584 |

| 22″ | 558.0 | 565.0 | 305 | 152 | 13 | 641 |

| 24″ | 609.0 | 616.0 | 305 | 152 | 13 | 692 |

stub end Types

Long Stub End SCH 40

ASME B16.9 Stub End SCH 10

ASME B16.9 Lap Joint Stub Ends

A234 Gr WPB Stub Ends EN 1092-1 Type 36

Short Stub End Sch 80

ASTM A234 WP11 Pipe stub end

ANSI B16.9 Stub End Type A

Carbon Steel Stub End Fittings

Stainless Steel Stub End Pipe Fittings

A403 Gr WP304 Stub Ends EN 1092-1 Type 35

Alloy Steel Schedule 10 stub end

Stub End Din 2642

Buttweld Stub Ends Fittings

MSS Type B Stub End

A403 WP316 sch 160 stub end

SA234 WP5 type c stub end

Lap Joint Stub End Dimensions

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel | Long Pattern | Short Pattern | Radius of Fillet | Diameter of Lap | |

|---|---|---|---|---|---|---|

| Max | Min | F | F | R | G | |

| 1/2 | 22.8 | 20.5 | 76 | 51 | 3 | 35 |

| 3/4 | 28.1 | 25.9 | 76 | 51 | 3 | 43 |

| 1 | 35.0 | 32.6 | 102 | 51 | 3 | 51 |

| 1-1/4 | 43.6 | 41.4 | 102 | 51 | 5 | 64 |

| 1-1/2 | 49.9 | 47.5 | 102 | 51 | 6 | 73 |

| 2 | 62.4 | 59.5 | 152 | 64 | 8 | 92 |

| 2-1/2 | 75.3 | 72.2 | 152 | 64 | 8 | 105 |

| 3 | 91.3 | 88.1 | 152 | 64 | 10 | 127 |

| 3-1/2 | 104.0 | 100.8 | 152 | 76 | 10 | 140 |

| 4 | 116.7 | 113.5 | 152 | 76 | 11 | 157 |

| 5 | 144.3 | 140.5 | 203 | 76 | 11 | 186 |

| 6 | 171.3 | 167.5 | 203 | 89 | 13 | 216 |

| 8 | 222.1 | 218.3 | 203 | 102 | 13 | 270 |

| 10 | 277.2 | 272.3 | 254 | 127 | 13 | 324 |

| 12 | 328.0 | 323.1 | 254 | 152 | 13 | 381 |

| 14 | 359.5 | 354.8 | 305 | 152 | 13 | 413 |

| 16 | 411.0 | 405.6 | 305 | 152 | 13 | 470 |

| 18 | 462 | 456 | 305 | 152 | 13 | 533 |

| 20 | 514 | 507 | 305 | 152 | 13 | 584 |

| 22 | 565 | 558 | 305 | 152 | 13 | 641 |

| 24 | 616 | 609 | 305 | 152 | 13 | 692 |

Stub End MSS SP 43 Dimensions

|

STUB ENDS – ANSI B 16.9 and MSS SP-43 dimension |

|||||||

|---|---|---|---|---|---|---|---|

| inches | ND | mm | Diameter of lap |

Radius of fillet |

Length F | ||

|

D |

G | R | R1 | MSS SP43 | ANSI B16.9 | ||

| 1/2 | 15 | 21,34 | 34,92 | 3,17 | 0,80 | 50,80 | 76,20 |

| 3/4 | 20 | 26,67 | 42,86 | 3,17 | 0,80 | 50,80 | 76,20 |

| 1 | 25 | 33,40 | 50,80 | 3,17 | 0,80 | 50,80 | 101,60 |

| 1 1/4 | 32 | 42,16 | 63,50 | 4,76 | 0,80 | 50,80 | 101,60 |

| 1 1/2 | 40 | 48,26 | 73,00 | 6,35 | 0,80 | 50,80 | 101,60 |

| 2 | 50 | 60,32 | 92,10 | 7,93 | 0,80 | 63,50 | 152,40 |

| 2 1/2 | 65 | 73,02 | 104,80 | 7,93 | 0,80 | 63,50 | 152,40 |

| 3 | 80 | 88,90 | 127,00 | 9,52 | 0,80 | 63,50 | 152,40 |

| 3 1/2 | 90 | 101,60 | 139,70 | 9,52 | 0,80 | 76,20 | 152,40 |

| 4 | 100 | 114,30 | 157,20 | 11,11 | 0,80 | 76,20 | 152,40 |

| 5 | 125 | 141,30 | 185,70 | 11,11 | 1,58 | 76,20 | 203,20 |

| 6 | 150 | 168,27 | 215,90 | 12,70 | 1,58 | 88,90 | 203,20 |

| 8 | 200 | 219,07 | 269,80 | 12,70 | 1,58 | 101,60 | 203,20 |

| 10 | 250 | 273,05 | 323,80 | 12,70 | 1,58 | 127,00 | 254,00 |

| 12 | 300 | 323,85 | 381,00 | 12,70 | 1,58 | 152,40 | 254,00 |

| 14 | 350 | 355,60 | 412,70 | 12,70 | 1,58 | 152,40 | 304,80 |

| 16 | 400 | 406,40 | 469,90 | 12,70 | 1,58 | 152,40 | 304,80 |

| 18 | 450 | 457,20 | 533,40 | 12,70 | 1,58 | 152,40 | 304,80 |

| 20 | 500 | 508,00 | 584,20 | 12,70 | 1,58 | 152,40 | 304,80 |

| 22 | 550 | 558,80 | 641,30 | 12,70 | 1,58 | 152,40 | 304,80 |

| 24 | 600 | 609,60 | 692,10 | 12,70 | 1,58 | 152,40 | 304,80 |

| The lap thickness T shall not be less than nominal pipe wall thickness t | |||||||

Weight Chart Of pipe stub end

| NPS inches |

STUB ENDS | |||

| Sch. 5S |

Sch. 10S |

Sch. 40S |

Sch. 80S |

|

| 1/2 | 0.06 | 0.08 | 0.12 | 0.13 |

| 3/4 | 0.07 | 0.09 | 0.15 | 0.17 |

| 1 | 0.09 | 0.15 | 0.20 | 0.25 |

| 1 1/4 | 0.13 | 0.20 | 0.30 | 0.35 |

| 1 1/2 | 0.16 | 0.25 | 0.38 | 0.46 |

| 2 | 0.25 | 0.40 | 0.55 | 0.75 |

| 2 1/2 | 0.35 | 0.50 | 0.80 | 1.00 |

| 3 | 0.50 | 0.60 | 1.10 | 1.50 |

| 4 | 0.70 | 1.00 | 1.80 | 2.50 |

| 5 | 1.00 | 1.25 | 2.50 | 3.50 |

| 6 | 1.60 | 1.95 | 3.70 | 5.50 |

| 8 | 2.50 | 3.10 | 5.90 | 10.0 |

| 10 | 4.00 | 4.90 | 10.5 | 14.0 |

| 12 | 6.60 | 7.10 | 15.0 | 20.0 |

| 14 | 6.40 | 7.80 | 15.5 | 20.5 |

| 16 | 7.90 | 9.00 | 18.0 | 24.0 |

| 18 | 9.30 | 10.5 | 21.0 | 28.0 |

| 20 | 12.0 | 13.5 | 23.5 | 31.0 |

| 24 | 16.5 | 19.0 | 28.5 | 38.0 |

| Approximate weights in kg, density 8 kg/dm3 | ||||

Stub Ends Length

Facing: 125-250 RMS (smooth finish)

welded version = w

= s seamless execution

| Nominal | Schedule | D | t | G | F | R. Max. | kg / St. | |

|---|---|---|---|---|---|---|---|---|

| 1/2 “ | 10s | 21.3 | 2.11 | 34.9 | 50.8 | 3.18 | 0.07 | s |

| 40s | 2.77 | 0.09 | s | |||||

| 3/4 “ | 10s | 26.7 | 2.11 | 42.9 | 50.8 | 3.18 | 0.10 | s |

| 40s | 2.87 | 0.12 | s | |||||

| 1 “ | 10s | 33.4 | 2.77 | 50.8 | 50.8 | 3.18 | 0.16 | s / w |

| 40s | 3.38 | 0.17 | s | |||||

| 1 1/4 “ | 10s | 42.2 | 2.77 | 63.5 | 50.8 | 4.76 | 0.22 | s |

| 40s | 3.56 | 0.25 | s | |||||

| 1 1/2 “ | 10s | 48.3 | 2.77 | 73.0 | 50.8 | 6.35 | 0.25 | s / w |

| 40s | 3.68 | 0.31 | s | |||||

| 2 “ | 10s | 60.3 | 2.77 | 92.1 | 63.5 | 7.94 | 0.43 | s / w |

| 40s | 3.91 | 0.61 | s | |||||

| 2 1/2 “ | 10s | 73.0 | 3.05 | 104.8 | 63.5 | 7.94 | 0.57 | s / w |

| 40s | 5.16 | 0.80 | s | |||||

| 3 “ | 10s | 88.9 | 3.05 | 127.0 | 63.5 | 9.53 | 0.73 | s / w |

| 40s | 5.49 | 1.13 | s | |||||

| 4 “ | 10s | 114.3 | 3.05 | 157.2 | 76.2 | 11.11 | 1.09 | s / w |

| 40s | 6.02 | 1.87 | s | |||||

| 5 “ | 10s | 141.3 | 3.40 | 185.7 | 76.2 | 11.11 | 1.47 | s / w |

| 40s | 6.55 | 2.28 | s | |||||

| 6 “ | 10s | 168.3 | 3.40 | 215.9 | 88.9 | 12.70 | 2.15 | s / w |

| 40s | 7.11 | 3.57 | s / w | |||||

| 8 “ | 10s | 219.1 | 3.76 | 269.9 | 101.6 | 12.70 | 3.22 | s / w |

| 40s | 8.18 | 6.07 | s / w | |||||

| 10 “ | 10s | 273.1 | 4.19 | 323.9 | 127.0 | 12.70 | 5.13 | w |

| 40s | 9.27 | 10.07 | w | |||||

| 12 “ | 10s | 323.9 | 4.57 | 381.0 | 152.4 | 12.70 | 8.16 | w |

| 40s | 9.53 | 14.29 | w | |||||

| 14 “ | 10s | 355.6 | 4.78 | 412.8 | 152.4 | 12.70 | 10.89 | w |

| 40s | 9.53 | 17.15 | w | |||||

| 16 “ | 10s | 406.4 | 4.78 | 469.9 | 152.4 | 12.70 | 12.70 | w |

| 40s | 9.53 | 20.41 | w | |||||

| 18 “ | 10s | 457.2 | 4.78 | 533.4 | 152.4 | 12.70 | 17.24 | w |

| 20 “ | 10s | 508.0 | 5.54 | 584.2 | 152.4 | 12.70 | 21.77 | w |

| 24 “ | 10s | 609.6 | 6.35 | 692.2 | 152.4 | 12.70 | 27.22 | w |