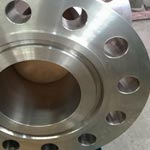

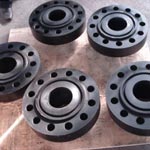

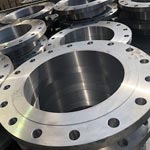

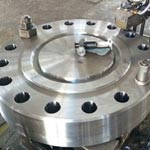

Ring Type Joint (RTJ) flanges are high-performance flanges designed for critical applications where high pressure and temperature conditions prevail. Manufactured from premium stainless steel grades such as SS 304, SS 316, and other high-quality alloys, these flanges provide exceptional durability, corrosion resistance, and strength, making them ideal for industries like oil and gas, petrochemical, chemical processing, and power generation.

An RTJ flange features a precision-machined groove in which a metallic ring gasket is seated to create a secure, leak-proof metal-to-metal seal. This design helps withstand extreme pressures, ensuring robust connections in challenging environments. Available in various sizes and specifications, Indian manufacturers offer RTJ flanges compliant with ASME, ANSI, API, and other global standards, with customization options to meet unique application requirements.

Leading manufacturers in India provide RTJ flanges with high-quality finishes, strict dimensional accuracy, and thorough testing protocols to guarantee reliable performance in critical pipelines and process equipment.

Specification of ring type joint weld neck flange

| ASME B16.5 RTJ Flange Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| class 300 rtj flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| ring type joint blind flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 ring type joint weld neck flange |

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K ring type joint blind flange |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar class 300 rtj flange |

| ring type joint weld neck flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS ring type joint orifice flange |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar class 900 rtj flange |

| Most common types of Ring Type Joint Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Production technique |

|

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized RTJ Flange |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Manufacturer of |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Origin | Indian / West Europe / Japan / USA / Korean |

| class 300 rtj flange Uses & application |

|

| Export to | Indonesia, Ukraine, India, Ireland, Singapore, Saudi Arabia, Spain, Dubai, Peru, Thailand, Korea, Iran, Canada, USA, Brazil, Egypt, Oman, etc |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Type of RTJ Flanges

ASME B16.5 RTJ Flange

ASME B16.5 Ring Type Joint Flanges

Ring type joint weld neck flange EN 1092-1 Type 02

EN 1092-2 PN16 ring type joint orifice flange

ANSI B16.5 rtj blind flange

ASME B16.47 Series a rtj wn flange

Duplex Steel Forged blind flange ring type joint

MSS SP-44 weld neck ring type joint flange

AWWA C207 Class d orifice flange ring type joint

Octagonal Ring Type Joint Flange

ASME B16.47 Series b rtj weld neck flange

ASTM A182 F304 RTJ Reducing Flange

ANSI B16.5 Class 150 rtj type flange

ASME B16.5 Class 300 ring type joint blind flange

ASTM A105 Carbon Steel RTJ End Flange

ASTM A694 F52 Flange RTJ Class 5000

Material of ring type joint blind flange

| Austenitic Stainless Steel RTJ Reducing Flange |

|

| Carbon Steel ring type joint orifice flange |

|

| Alloy Steel High-Temp ring type joint blind flange |

|

| Alloy Steel Low-Temp class 900 rtj flange |

|

| Nickel Alloy ring type joint weld neck flange |

|

| Titanium class 900 rtj flange |

|

150 Ring Type Joint Flanges

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Widthrong>of Ring |

HEIGHT OF RING |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1 |

47.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

63.5 |

R15 |

4.1 |

|

1 1/4 |

57.2 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

73.2 |

R17 |

4.1 |

|

1 1/2 |

65.1 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

82.6 |

R19 |

4.1 |

|

2 |

82.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

101.6 |

R22 |

4.1 |

|

2 1/2 |

101.6 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

120.7 |

R25 |

4.1 |

|

3 |

114.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

133.4 |

R29 |

4.1 |

|

3 1/2 |

131.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

153.9 |

R33 |

4.1 |

|

4 |

149.2 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

171.5 |

R36 |

4.1 |

|

5 |

171.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

193.5 |

R40 |

4.1 |

|

6 |

193.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

218.9 |

R43 |

4.1 |

|

8 |

247.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

273.1 |

R48 |

4.1 |

|

10 |

304.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

330.2 |

R52 |

4.1 |

|

12 |

381.0 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

406.4 |

R56 |

4.1 |

|

14 |

396.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

425.5 |

R59 |

3.0 |

|

16 |

454.0 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

482.6 |

R64 |

3.0 |

|

18 |

517.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

546.1 |

R68 |

3.0 |

|

20 |

558.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

596.9 |

R72 |

3.0 |

|

24 |

673.1 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

711.2 |

R76 |

3.0 |

Class 300 rtj flange dimensions and 600# rtj flange dimensions

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Widthrong>of Ring |

HEIGHT OF RING |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|||

|

OVal |

Octagonal |

|||||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

Class 300 |

Class 400 |

Class 600 |

||

|

1/2 |

34.1 |

6.4 |

11.1 |

9.5 |

4.3 |

7.1 |

5.6 |

50.8 |

R11 |

3.0 |

– |

3.0 |

|

3/4 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

63.5 |

R13 |

4.1 |

– |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

69.9 |

R16 |

4.1 |

– |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

79.5 |

R18 |

4.1 |

– |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

90.4 |

R20 |

4.1 |

– |

4.1 |

|

2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

108.0 |

R23 |

5.6 |

– |

4.8 |

|

2 1/2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

127.0 |

R26 |

5.6 |

– |

4.8 |

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

146.1 |

R31 |

5.6 |

– |

4.8 |

|

3 1/2 |

131.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

158.8 |

R34 |

5.6 |

– |

4.8 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

174.8 |

R37 |

5.6 |

5.6 |

4.8 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

209.6 |

R41 |

5.6 |

5.6 |

4.8 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

5.6 |

5.6 |

4.8 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

301.8 |

R49 |

5.6 |

5.6 |

4.8 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

355.6 |

R53 |

5.6 |

5.6 |

4.8 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

412.8 |

R57 |

5.6 |

5.6 |

4.8 |

|

14 |

419.1 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

457.2 |

R61 |

5.6 |

5.6 |

4.8 |

|

16 |

469.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

508.0 |

R65 |

5.6 |

5.6 |

4.8 |

|

18 |

533.4 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

574.8 |

R69 |

5.6 |

5.6 |

4.8 |

|

20 |

584.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

635.0 |

R73 |

5.6 |

5.6 |

4.8 |

|

24 |

692.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

749.3 |

R77 |

6.4 |

6.4 |

5.6 |

Class 900 rtj flange dimensions

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Widthrong>of Ring |

HEIGHT OF RING |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

3 |

123.8 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

155.4 |

R31 |

4.1 |

|

4 |

149.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

180.8 |

R37 |

4.1 |

|

5 |

181.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

215.9 |

R41 |

4.1 |

|

6 |

211.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

241.3 |

R45 |

4.1 |

|

8 |

269.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

307.8 |

R49 |

4.1 |

|

10 |

323.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

362.0 |

R53 |

4.1 |

|

12 |

381.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

419.1 |

R57 |

4.1 |

|

14 |

419.1 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

466.9 |

R62 |

4.1 |

|

16 |

469.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

523.7 |

R66 |

4.1 |

|

18 |

533.4 |

19.1 |

25.4 |

23.8 |

11.1 |

19.8 |

12.7 |

593.9 |

R70 |

4.8 |

|

20 |

584.2 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

647.7 |

R74 |

4.8 |

|

24 |

692.2 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

771.7 |

R78 |

5.6 |

Class 1500 rtj flange dimensions and 1500# rtj flange dimensions

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Widthrong>of Ring |

HEIGHT OF RING |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

39.7 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

60.5 |

R12 |

4.1 |

|

3/4 |

44.5 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

66.8 |

R14 |

4.1 |

|

1 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

71.4 |

R16 |

4.1 |

|

1 1/4 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

81.0 |

R18 |

4.1 |

|

1 1/2 |

68.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

92.2 |

R20 |

4.1 |

|

2 |

95.3 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

124.0 |

R24 |

3.0 |

|

2 1/2 |

108.0 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

136.7 |

R27 |

3.0 |

|

3 |

136.5 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

168.4 |

R35 |

3.0 |

|

4 |

161.9 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

193.8 |

R39 |

3.0 |

|

5 |

193.7 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

228.6 |

R44 |

3.0 |

|

6 |

211.2 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

247.7 |

R46 |

3.0 |

|

8 |

269.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

317.5 |

R50 |

4.1 |

|

10 |

323.9 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

371.6 |

R54 |

4.1 |

|

12 |

381.0 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

438.2 |

R58 |

4.8 |

|

14 |

419.1 |

25.4 |

33.4 |

31.8 |

17.3 |

27.0 |

15.9 |

489.0 |

R64 |

5.6 |

|

16 |

469.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

546.1 |

R67 |

7.9 |

|

18 |

533.4 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

612.9 |

R71 |

7.9 |

|

20 |

584.2 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

673.1 |

R75 |

9.7 |

|

24 |

692.2 |

34.9 |

44.5 |

41.3 |

24.8 |

36.5 |

20.6 |

793.8 |

R79 |

11.2 |

Class 2500 rtj flange dimensions, 2500# rtj flange dimensions and 2500 lb rtj flange dimensions

|

Nominal Pipe Size |

Pitch Diam. of Ring and Groove |

Widthrong>of Ring |

HEIGHT OF RING |

Widthlat on Octagonal Rings |

Widthroove |

Depth of Groove |

Diameter of Raised Face for Ring Joint or Lapped |

Ring Number |

Approximate Distande Between Flange of Ring Joints When Ring is Compressed |

|

|

OVal |

Octagonal |

|||||||||

|

P |

A |

B |

H |

C |

F |

E(L*) |

K(Min) |

|||

|

1/2 |

42.9 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

65.0 |

R13 |

4.1 |

|

3/4 |

50.8 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

73.2 |

R16 |

4.1 |

|

1 |

60.3 |

8.0 |

14.3 |

12.7 |

5.2 |

8.7 |

6.4 |

82.6 |

R18 |

4.1 |

|

1 1/4 |

72.2 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

101.6 |

R21 |

3.0 |

|

1 1/2 |

82.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

114.3 |

R23 |

3.0 |

|

2 |

101.6 |

11.1 |

17.5 |

15.9 |

7.7 |

11.9 |

7.9 |

133.4 |

R26 |

3.0 |

|

2 1/2 |

111.1 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

149.4 |

R28 |

3.0 |

|

3 |

127.0 |

12.7 |

19.1 |

17.5 |

8.7 |

13.5 |

9.5 |

168.4 |

R32 |

3.0 |

|

4 |

157.2 |

15.9 |

22.2 |

20.7 |

10.5 |

16.7 |

11.1 |

203.2 |

R38 |

4.1 |

|

5 |

190.5 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

241.3 |

R42 |

4.1 |

|

6 |

228.6 |

19.1 |

25.4 |

23.8 |

12.3 |

19.8 |

12.7 |

279.4 |

R47 |

4.1 |

|

8 |

279.4 |

22.2 |

28.6 |

27.0 |

14.8 |

23.0 |

14.3 |

339.9 |

R51 |

4.8 |

|

10 |

342.9 |

28.6 |

36.5 |

34.9 |

19.8 |

30.2 |

17.5 |

425.5 |

R55 |

6.4 |

|

12 |

406.4 |

31.8 |

39.7 |

38.1 |

22.3 |

33.4 |

17.5 |

495.3 |

R60 |

7.9 |

ASME B16.5 Ring Type Joint Flanges Pressure Ratings

| Flanges pressure rating

in psig for RTJ Ring Type Joint Flange ASME |

|||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |