Our extensive selection of Hastelloy pipe fittings at Repute Steel & Engineering Company includes 45- and 90-degree socket-welded short radius elbows as well as pipe bends. Designed to function remarkably well in extremely harsh situations, these fittings are a dependable option for a variety of sectors. Hastelloy, with its unique combination of nickel, molybdenum, and chromium, enjoys high respect for its resistance to both reductive and oxidative solutions.

Our ASTM B366-approved Hastelloy Buttweld Elbow fittings are better at resisting intergranular corrosion and can be welded more easily, which are both traits of low-carbon alloys. This ensures long-lasting performance in demanding applications.

When corrosive chemicals and high temperatures are present, hastelloy pipe fittings are the best option. Hastelloy alloys resist carbide precipitation, preventing grain boundary damage even in the heat-affected zone of welds. The DIN 2.4819 Pipe Reducing Tee is very helpful in these situations because the chemical processing industry can use fittings in their "as-welded" condition. These fittings also provide exceptional resistance against aggressive substances such as seawater, brine, ferric and cupric chlorides, chlorine, and chloride-based solutions.

The pulp, paper, and textile sectors extensively use Repute Steel & Engineering Company's hastelloy pipe fittings, utilizing hypochlorite, a typical bleaching chemical. Companies that work with acidic chemicals like these fittings because they are very resistant to acids that break things down, like formic and acetic acids, as well as to acetic anhydride and chlorine dioxide solutions.

Being one of the top manufacturers of hastelloy weld fittings in India, we are committed to offering long-lasting, corrosion-resistant solutions that satisfy the demanding needs of many sectors.

Standard Specification for Hastelloy Pipe Fittings

| Grade | C276 |

|---|---|

| Specifications | ASTM B366/ ASME SB366 |

| Bending Radius | Radius=1 D, 2D, 3 D, 5D, 6D, 8 D, 10D |

| Dimension | ASME/ ANSI B16.9 | ASME B16.28 | MSS-SP-43 | BS1560 | BS4504 | BS10 |

| Thickness of Fitting | SCH10, SCH 20, SCH30, STD SCH40, SCH80, SCH60, XS, SCH100, SCH 120, SCH140, SCH 160, XXS available with NACE MR 01-75 |

| Types | Welded | Seamless | Fabricated |

| Size Ranges | ½” NB to 24″ NB in Schedule 10s, 40s, 80s, 160s, XXS. |

| Size Range | Seamless Butt-Weld Fitting: From 1/2″ - 10″ Welded ButtWeld Fitting: From 1/2″ - 48″ |

| Process of Manufacturing | Push, Press, Cast, Forge. |

Chemical Formula of C276 Hastelloy End Cap

| Chemicals | Content (%) |

| Fe | 4 – 7 |

| Si | 0.08 maximum |

| C | 0.010 maximum |

| S | 0.03 maximum |

| Ni | Bal |

| Mn | 1.0 maximum |

| Cr | 14.5 – 16.5 |

| V | 0.35 maximum |

| Mo | 15 – 17 |

| Co | 2.5 maximum |

| W | 3 – 4.5 |

| P | 0.04 maximum |

Most famous types of Hastelloy Pipe Fittings

Hastelloy c276 6 inch welded stainless steel pipe fittings

MSS-SP75 16-60" Hastelloy C-276 ASTM B366 N10276 Long Radius Pipe Elbow

Hastelloy C276 90 degree long radius pipe elbow r=1.5d ASME B16.9

ASTM B366 N10276 Hastelloy C-276 2.4819 LR SR 3D 5D Pipe Elbow Return Bend

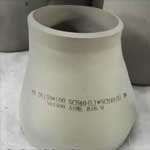

ASTM B462 UNS N10276 Pipe Fittings Con. Reducer

Pipe Straight tee 5000psi 14mm c-276 hastelloy high pressure

ASTM B366 Hastelloy C276 UN N10276 Nickel base LR Pipe Elbow Reducer

Hastelloy C276 smls 90 degree pipe elbow ASTM B16.9

Equivalent of Hastelloy C276 Socket Weld Fittings

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | EN | JIS | OR | GOST |

|---|---|---|---|---|---|---|---|

| Hastelloy C276 | N10276 | 2.4819 | – | NiMo16Cr15W | NW 0276 | ЭП760 | ХН65МВУ |