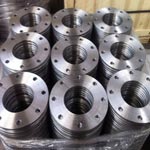

We are suppliers of ANSI B16.5 stainless steel plate flanges and manufacturers of nickel plate flanges in Mumbai, India. ANSI B16.5 plate flanges, commonly used in fuel and water pipelines, connect two flange plates with a gasket in between. These flanges have bolt holes around the perimeter, facilitating the creation of junctions, joints, and tees. The Hastelloy C22 plate flange is particularly valued for its excellent corrosion resistance, durability, and reliable performance. DIN86029 PN10 plate flanges are designed for easy assembly and disassembly with pipes, making them versatile in various applications. Carbon steel plate flanges can be forged or manufactured from plate material.

We offer ANSI B16.5 Class 150 plate flanges that are used widely in industries such as heavy engineering, automotive, railways, and pipeline engineering. Our DIN86029 PN10 plate flanges are fabricated to match the wall thickness and dimensions of compatible pipes. These flanges meet strict standards for tolerances, markings, dimensions, pressure and temperature ratings, and material specifications, as well as design requirements for flanged fittings in piping systems.

We manufacture stainless steel plate flanges and pipe fittings adhering to international standards, including JIS, ANSI, EN, DIN, BS, and GB. ASME B16.5 stainless steel flange plates provide a defect-free, extended service life with a superior grain structure compared to forged or cast alternatives, helping reduce normal maintenance costs.

Our flat-faced plate flanges range from 1/2" to 200" in size, with pressure ratings from 150 lbs to 3000 lbs. The ASTM A182 stainless steel plate flange meets both the Boiler and Pressure Vessel Code and B31 Piping Codes, offering versatility across various high-demand applications.

150 Plate Flanges Specification

| ASME B16.5 Plate Flanges Size Chart | 1/2" (15 NB) to 48" (1200NB) DN10~DN5000 |

|---|---|

| Carbon Steel Plate Flanges Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS Plate Flange |

| Plate Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 Plate Flange |

| Plate Flange Standard | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Plate Flange, ASME Plate Flange, BS Plate Flange, DIN Plate Flange, EN Plate Flange, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| JIS Flat Faced Plate Flanges | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K Plate Flange |

| UNI Stainless Steel Plate Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Plate Flange |

| EN ANSI B16.5 Plate Flanges | 6Bar 10Bar 16Bar 25Bar 40Bar Plate Flange |

| Most common types of Flange Plate | Threaded / Forged / Screwed / Plate |

| ANSI B16.5 Plate Flange manufacturers |

ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc.

|

| Production technique |

|

| Coating For ASME B16.5 Plate Flange Manufacturers | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized Plate Flange |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Origin | Indian / West Europe / Japan / USA / Korean |

| Connect Type/ Flange Plate Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Plate Flange Uses & application |

|

| Export to DIN86029 PN10 Plate Flanges | Indonesia, Ukraine, Saudi Arabia, Ireland, Singapore, Thailand, Korea, Iran, India, Egypt, Spain, Canada, USA, Brazil, Oman, Dubai, Peru, etc |

| Special design |

As per your drawing AS, ANSI, BS, DIN and JIS |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

| ASME B16.5 Plate Flange Manufacturers In India | |

Type of RTJ Flanges

EN 1092-1 GP240GH Flat ASME B16.5 Plate Flanges, PN16, DN100

ASTM A182 F304 Plate Flange, PN 16, DN 125

DIN 2576, DN250, PN10 S235JR Plate Flange

EN1092-1, PN16, DN200, ASTM A105 Flat Plate Flange

ASME SA240 SS310S Plate Flange, 45mm, 1575mm

ASME B16.5 Plate Flange, DN80, PN16, UNI2278-67

EN1092-1 Type 01, ANSI B16.5 Plate Flange, Class 120, 6 Inch

Flat Plate Flange, ASTM A182, A350, PN20, PN50

ASTM A182 FF Back Flange, Class D, DN700

JIS B2238 ANSI B16.5 Plate Flanges, FF, PN420

EN 1092 ASTM A105 Plate Flange, Black, 8 Inch

DIN 2501 Flat Flange, 2 Inch, PN16

Black Cast Steel Plate Flange, DN100, FF, PN16

DIN 2576 Plate Flange, S235JR, DN3000, PN10

SA240 SS310S Plate Flange, ID 1375mm, BCD 1472mm, OD 1575mm

UNI 2278-67 Flat Plate Flange, PN16, DN80

Carbon Steel Plate Flange Material

| Stainless Steel Plate Flanges | ASTM/ASME A/SA182 F304, F304L, F316, F316L, ASTM/ASME A/SA351 CF8, CF3, CF8M, CF3M, DIN 1.4301, DIN 1.4306, DIN 1.4401, DIN 1.4404, DIN 1.4308, DIN 1.4408, DIN 1.4306, DIN 1.4409 |

|---|---|

| Carbon Steel Plate Flanges | ASTM/ASME A/SA105 A/SA105N & A/SA216-WCB, DIN 1.0402, DIN 1.0460, DIN 1.0619, Die Steel, ASTM A105 / ASME SA105, A105N, ASTM A350 LF2 / ASME SA350, High Yield CS ASTM A694 / A694 (F52 F56 F60 F65 F70 F80) |

| Alloy Steel Plate Flanges | ASTM A182 / ASME SA182 F5, F9, F11, F12, F22, F91 |

| Titanium Plate Flange | ASTM B381 / ASME SB381, Titanium Gr. 1, Titanium Gr. 2, Titanium Gr. 4,

Titanium Gr. 5, Titanium Gr. 7 ASTM R50250/GR.1 | R50400/GR.2 | R50550/GR.3 | R50700/GR.4 | GR.6 |R52400/GR.7 | R53400/GR.12 | R56320/GR.9 |R56400/GR.5 |

| Duplex Steel Plate Flanges | S31803 / S32205 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Copper Plate Flange | T1, T2, C10100, C10200, C10300, C10400, C10500, C10700, C10800, C10910,C10920, TP1, TP2, C10930, C11000, C11300, C11400, C11500, C11600, C12000,C12200, C12300, TU1, TU2, C12500, C14200, C14420, C14500, C14510, C14520, C14530, C17200, C19200, C21000, C23000, C26000, C27000, C27400, C28000, C33000, C33200, C37000, C44300, C44400, C44500, C60800, C63020, C68700, C70400, C70600, C70620, C71000, C71500, C71520, C71640, etc |

| Copper Nickel Plate Flanges | ASTM / ASME SB 61 / 62 / 151 / 152, Copper Nickel 90/10 (C70600 ), Cupro Nickel 70/30 (C71500), UNS C71640 |

| Inconel Plate Flanges | ASTM B564 / ASME SB564, Inconel 600, 601, 625, 718, 783, 690, x750 Flange |

| Hastelloy C22 Plate Flange | ASTM B564 / ASME SB564, Hastelloy C276 (UNS N10276), C22 (UNS N06022), C4, C2000, B2, B3, X Flange |

| Monel Plate Flange | ASTM B564 / ASME SB564, Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500) |

| Alloy 20 Plate Flanges | ASTM B462 / ASME SB462, Carpenter® 20 Alloy, Alloy 20Cb-3 |

| Aluminium Plate Flange | 5052 /6061/ 6063 / 2017 / 7075 / etc. |

| Nickel Plate Flange | ASTM B564 / ASME SB564, Nickel 200, Nickel 201, Nickel 205, Nickel 205LC |

| Brass Plate Flange | 3602 / 2604 / H59 / H62 / etc. |

| Super Duplex Plate Flange | S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61 |

| Inconel Plate Flanges | ASTM B564 / ASME SB564, Incoloy 800, 800H, 800HT (UNS N08800), 825 (UNS N08825), 925 Flange |

| 254 Smo Plate Flange | ASTM A182 / ASME SA182, SMO 254/6Mo, UNS S31254, DIN 1.4547 |

| Nimonic Plate Flange | Nimonic 75, Nimonic 80A, Nimonic 90 |

| Other Plate Flange material | Tin bronze, Alumunum bronze, Lead bronze |

| ASME B16.5 Plate Flange Manufacturers In India | |

Flange Plate Weight Chart

| Nominal Pipe Size | Diameter of Pipe | Flange Dimension | Nuts & Bolts | Approx. Flange Weight | |||||

| Flange I.D | Flange Dia | Thk of Flange | Dia of Bolt Circle | No. of Holes | Dia of Bolt Holes | ||||

| DN | ISO | DIN | d5 | D | b | k | d2 | KG /PCS | |

| 10 | – | 14 | 14.5 | 90 | 14 | 60 | 4 | 14 | 0.61 |

| 17.2 | – | 17.7 | 90 | 14 | 60 | 4 | 14 | 0.6 | |

| 15 | – | 20 | 21 | 95 | 14 | 65 | 4 | 14 | 0.67 |

| 21.3 | – | 22 | 95 | 14 | 65 | 4 | 14 | 0.67 | |

| 20 | – | 25 | 26 | 105 | 16 | 75 | 4 | 14 | 0.94 |

| 26.9 | – | 27.6 | 105 | 16 | 75 | 4 | 14 | 0.94 | |

| 25 | – | 30 | 31 | 115 | 16 | 85 | 4 | 14 | 1.13 |

| 33.7 | – | 34.4 | 115 | 16 | 85 | 4 | 14 | 1.11 | |

| 32 | – | 38 | 39 | 140 | 16 | 100 | 4 | 18 | 1.66 |

| 42.4 | – | 43.1 | 140 | 16 | 100 | 4 | 18 | 1.62 | |

| 40 | – | 44.5 | 45.5 | 150 | 16 | 110 | 4 | 18 | 1.89 |

| 48.3 | – | 49 | 150 | 16 | 110 | 4 | 18 | 1.85 | |

| 50 | – | 57 | 58.1 | 165 | 18 | 125 | 4 | 18 | 2.5 |

| 60.3 | – | 61.1 | 165 | 18 | 125 | 4 | 18 | 2.46 | |

| 65 | 76.1 | – | 77.1 | 185 | 18 | 145 | 4 | 18 | 2.99 |

| 80 | 88.9 | – | 90.3 | 200 | 20 | 160 | 8 | 18 | 3.61 |

| 100 | – | 108 | 109.6 | 220 | 20 | 180 | 8 | 18 | 4.17 |

| 114.3 | – | 115.9 | 220 | 20 | 180 | 8 | 18 | 3.99 | |

| 125 | – | 133 | 134.8 | 250 | 22 | 210 | 8 | 18 | 5.66 |

| 139.7 | – | 141.6 | 250 | 22 | 210 | 8 | 18 | 5.41 | |

| 150 | – | 159 | 161.1 | 285 | 22 | 240 | 8 | 22 | 6.97 |

| 168.3 | – | 170.5 | 285 | 22 | 240 | 8 | 22 | 6.55 | |

| 175 | 193.7 | – | 196.1 | 315 | 24 | 270 | 8 | 22 | 8.42 |

| 200 | 219.1 | – | 221.8 | 340 | 24 | 295 | 8 | 22 | 9.28 |

| 250 | – | 267 | 270.2 | 395 | 26 | 350 | 12 | 22 | 12.36 |

| 273 | – | 276.2 | 395 | 26 | 350 | 12 | 22 | 11.85 | |

| 300 | 323.9 | – | 327.6 | 445 | 26 | 400 | 12 | 22 | 13.61 |

| 350 | 355.6 | – | 359.7 | 505 | 28 | 460 | 16 | 22 | 20.35 |

| – | 368 | 372.2 | 505 | 28 | 460 | 16 | 22 | 18.77 | |

| 400 | 406.4 | – | 411 | 565 | 32 | 515 | 18 | 26 | 27.52 |

| – | 419 | 423.7 | 565 | 32 | 515 | 18 | 26 | 35.43 | |

| 450 | 457 | – | 462.3 | 615 | 38 | 565 | 20 | 26 | 35.11 |

| 500 | 508 | – | 613.6 | 670 | 38 | 620 | 20 | 26 | 40.2 |

| 600 | 610 | – | 615.5 | 780 | 40 | 725 | 20 | 26 | 51.87 |

JIS 5K Plate Flange Dimensions

|

Pipe |

Pipe |

Bo |

D |

t |

T |

G |

f |

r |

H |

X |

C |

Holes |

Bolt Dia. |

|||||||||

|

inch |

mm |

|||||||||||||||||||||

|

3/8 |

10 |

17.3 |

17.8 |

+0.5 |

75 |

+1.0 |

9 |

nbsp; +1.0 |

±1.0 |

42 |

±0.8 |

1 |

+2.0 |

+2.0 |

55 |

±0.5 |

4 |

12 |

||||

|

1/2 |

15 |

21.7 |

22.2 |

80 |

9 |

48 |

1 |

60 |

4 |

12 |

||||||||||||

|

3/4 |

20 |

27.2 |

27.7 |

85 |

10 |

52 |

1 |

65 |

4 |

12 |

||||||||||||

|

1 |

25 |

34.0 |

34.5 |

95 |

10 |

62 |

1 |

75 |

4 |

12 |

||||||||||||

|

1-1/4 |

32 |

42.7 |

43.2 |

115 |

12 |

72 |

2 |

90 |

4 |

15 |

||||||||||||

|

1-1/2 |

40 |

48.6 |

49.1 |

120 |

12 |

78 |

2 |

95 |

4 |

15 |

||||||||||||

|

2 |

50 |

60.5 |

61.1 |

130 |

14 |

88 |

2 |

105 |

4 |

15 |

||||||||||||

|

2-1/2 |

65 |

76.3 |

77.1 |

155 |

14 |

112 |

2 |

130 |

4 |

15 |

||||||||||||

|

3 |

80 |

89.1 |

90.0 |

180 |

14 |

125 |

2 |

145 |

4 |

19 |

||||||||||||

|

3-1/2 |

90 |

101.6 |

102.6 |

+1.0 |

190 |

14 |

135 |

2 |

155 |

4 |

19 |

|||||||||||

|

4 |

100 |

114.3 |

115.4 |

200 |

16 |

145 |

2 |

165 |

8 |

19 |

||||||||||||

|

5 |

125 |

139.8 |

141.2 |

235 |

16 |

180 |

2 |

200 |

8 |

19 |

||||||||||||

|

6 |

150 |

165.2 |

166.6 |

265 |

18 |

210 |

2 |

230 |

8 |

19 |

||||||||||||

|

7 |

175 |

190.7 |

192.1 |

300 |

18 |

235 |

±0.9 |

2 |

260 |

±0.6 |

8 |

23 |

||||||||||

|

8 |

200 |

216.3 |

218.0 |

320 |

+1.5 |

20 |

255 |

2 |

280 |

8 |

23 |

|||||||||||

|

9 |

225 |

241.8 |

243.7 |

345 |

20 |

280 |

2 |

305 |

12 |

23 |

||||||||||||

|

10 |

250 |

267.4 |

269.5 |

385 |

22 |

+1.5 |

32 |

320 |

2 |

5 |

286 |

290 |

345 |

12 |

23 |

|||||||

|

12 |

300 |

318.5 |

321.0 |

430 |

22 |

34 |

365 |

3 |

5 |

338 |

342 |

390 |

12 |

23 |

||||||||

|

14 |

350 |

355.6 |

358.1 |

480 |

24 |

36 |

405 |

3 |

5 |

378 |

382 |

435 |

12 |

25 |

||||||||

|

16 |

400 |

406.4 |

409.0 |

+1.5 |

540 |

24 |

36 |

465 |

3 |

5 |

432 |

436 |

495 |

16 |

25 |

|||||||

|

18 |

450 |

457.2 |

460.0 |

605 |

+2.0 |

24 |

40 |

525 |

3 |

5 |

495 |

500 |

555 |

±0.8 |

16 |

25 |

||||||

|

20 |

500 |

508.0 |

511.0 |

655 |

24 |

40 |

575 |

3 |

5 |

546 |

552 |

605 |

20 |

25 |

||||||||

|

22 |

550 |

558.8 |

562.0 |

720 |

26 |

42 |

630 |

3 |

5 |

597 |

603 |

665 |

20 |

27 |

||||||||

|

24 |

600 |

609.6 |

613.0 |

+2.0 |

770 |

26 |

44 |

680 |

±1.0 |

3 |

5 |

648 |

654 |

+2.5 |

715 |

20 |

27 |

|||||

|

26 |

650 |

660.4 |

664.0 |

825 |

26 |

48 |

735 |

3 |

5 |

702 |

+2.5 |

708 |

770 |

24 |

27 |

|||||||

|

28 |

700 |

711.2 |

715.0 |

875 |

26 |

48 |

785 |

3 |

5 |

751 |

758 |

820 |

24 |

27 |

||||||||

|

30 |

750 |

762.0 |

766.0 |

945 |

28 |

52 |

±1.5 |

840 |

3 |

5 |

802 |

810 |

880 |

24 |

33 |

|||||||

|

32 |

800 |

812.8 |

817.0 |

+2.5 |

995 |

28 |

52 |

890 |

3 |

5 |

854 |

+3.0 |

862 |

+3.0 |

930 |

24 |

33 |

|||||

|

34 |

850 |

863.6 |

868.0 |

1045 |

+2.5 |

28 |

54 |

940 |

3 |

5 |

904 |

912 |

980 |

±1.0 |

24 |

33 |

||||||

|

36 |

900 |

914.4 |

919.0 |

1095 |

30 |

56 |

990 |

3 |

5 |

956 |

964 |

1030 |

24 |

33 |

||||||||

|

40 |

1000 |

1016.0 |

1021.0 |

+3.0 |

1195 |

32 |

60 |

1090 |

±1.2 |

3 |

5 |

1058 |

+3.5 |

1066 |

+3.5 |

1130 |

28 |

33 |

||||

|

44 |

1100 |

1117.6 |

1123.0 |

1305 |

32 |

1200 |

3 |

1240 |

28 |

33 |

||||||||||||

|

48 |

1200 |

1219.2 |

1224.0 |

1420 |

34 |

1305 |

3 |

1350 |

32 |

33 |

||||||||||||

|

54 |

1350 |

1371.6 |

1377.0 |

1575 |

+3.0 |

34 |

1460 |

3 |

1505 |

±1.5 |

32 |

33 |

||||||||||

|

60 |

1500 |

1524.0 |

1529.0 |

1730 |

36 |

1615 |

3 |

1660 |

36 |

33 |

||||||||||||

JIS 10K Plate Flange Dimensions

|

Pipe |

Pipe |

Bo |

D |

t |

T |

G |

f |

r |

H |

X |

C |

Holes |

Bolt Dia. |

|||||||||

|

inch |

mm |

|||||||||||||||||||||

|

3/8 |

10 |

17.3 |

17.8 |

+0.5 |

90 |

+1.0 |

12 |

+1.0 |

±1.0 |

48 |

±0.8 |

1 |

+1.5 |

+1.5 |

65 |

±0.5 |

4 |

15 |

||||

|

1/2 |

15 |

21.7 |

22.2 |

95 |

12 |

52 |

1 |

70 |

4 |

15 |

||||||||||||

|

3/4 |

20 |

27.2 |

27.7 |

100 |

14 |

58 |

1 |

75 |

4 |

15 |

||||||||||||

|

1 |

25 |

34.0 |

34.5 |

125 |

14 |

70 |

1 |

90 |

4 |

19 |

||||||||||||

|

1-1/4 |

32 |

42.7 |

43.2 |

135 |

16 |

80 |

2 |

100 |

4 |

19 |

||||||||||||

|

1-1/2 |

40 |

48.6 |

49.1 |

140 |

16 |

85 |

2 |

105 |

4 |

19 |

||||||||||||

|

2 |

50 |

60.5 |

61.1 |

155 |

16 |

100 |

2 |

120 |

4 |

19 |

||||||||||||

|

2-1/2 |

65 |

76.3 |

77.1 |

175 |

18 |

120 |

2 |

140 |

4 |

19 |

||||||||||||

|

3 |

80 |

89.1 |

90.0 |

185 |

18 |

130 |

2 |

150 |

8 |

19 |

||||||||||||

|

3-1/2 |

90 |

101.6 |

102.6 |

+1.0 |

195 |

18 |

140 |

2 |

160 |

8 |

19 |

|||||||||||

|

4 |

100 |

114.3 |

115.4 |

210 |

18 |

155 |

2 |

175 |

8 |

19 |

||||||||||||

|

5 |

125 |

139.8 |

141.2 |

250 |

20 |

185 |

2 |

210 |

8 |

23 |

||||||||||||

|

6 |

150 |

165.2 |

166.6 |

280 |

22 |

+1.5 |

215 |

2 |

240 |

8 |

23 |

|||||||||||

|

7 |

175 |

190.7 |

192.1 |

305 |

+1.5 |

22 |

32 |

240 |

±0.9 |

2 |

6 |

208 |

212 |

265 |

±0.6 |

12 |

23 |

|||||

|

8 |

200 |

216.3 |

218.0 |

330 |

22 |

32 |

265 |

2 |

6 |

234 |

238 |

290 |

12 |

23 |

||||||||

|

9 |

225 |

241.8 |

243.7 |

350 |

22 |

34 |

285 |

2 |

6 |

260 |

264 |

310 |

12 |

23 |

||||||||

|

10 |

250 |

267.4 |

269.5 |

400 |

24 |

36 |

325 |

2 |

6 |

288 |

292 |

355 |

12 |

25 |

||||||||

|

12 |

300 |

318.5 |

321.0 |

445 |

24 |

38 |

370 |

3 |

6 |

340 |

346 |

400 |

16 |

25 |

||||||||

|

14 |

350 |

355.6 |

358.1 |

490 |

26 |

42 |

415 |

3 |

6 |

380 |

386 |

445 |

16 |

25 |

||||||||

|

16 |

400 |

406.4 |

409.0 |

+1.5 |

560 |

28 |

44 |

475 |

3 |

6 |

436 |

442 |

510 |

16 |

27 |

|||||||

|

18 |

450 |

457.2 |

460.0 |

620 |

+2.0 |

30 |

48 |

530 |

3 |

6 |

496 |

+2.0 |

502 |

+2.0 |

565 |

±0.8 |

20 |

27 |

||||

|

20 |

500 |

508.0 |

511.0 |

675 |

30 |

48 |

585 |

3 |

6 |

548 |

554 |

620 |

20 |

27 |

||||||||

|

22 |

550 |

558.8 |

562.0 |

745 |

32 |

52 |

±1.5 |

640 |

3 |

6 |

604 |

610 |

680 |

20 |

33 |

|||||||

|

24 |

600 |

609.6 |

613.0 |

+2.0 |

795 |

32 |

52 |

690 |

±1.0 |

3 |

6 |

656 |

+2.5 |

662 |

+2.5 |

730 |

24 |

33 |

||||

|

26 |

650 |

660.4 |

664.0 |

845 |

34 |

56 |

740 |

3 |

6 |

706 |

712 |

780 |

24 |

33 |

||||||||

|

28 |

700 |

711.2 |

715.0 |

905 |

34 |

58 |

800 |

3 |

6 |

762 |

770 |

840 |

24 |

33 |

||||||||

|

30 |

750 |

762.0 |

766.0 |

970 |

36 |

62 |

855 |

3 |

6 |

816 |

824 |

900 |

24 |

33 |

||||||||

|

32 |

800 |

812.8 |

817.0 |

+2.5 |

1020 |

+2.5 |

36 |

64 |

905 |

3 |

6 |

868 |

+3.0 |

876 |

+3.0 |

950 |

28 |

33 |

||||

|

34 |

850 |

863.6 |

868.0 |

1070 |

36 |

66 |

955 |

3 |

6 |

920 |

928 |

1000 |

±1.0 |

28 |

33 |

|||||||

|

36 |

900 |

914.4 |

919.0 |

1120 |

38 |

70 |

1005 |

±1.2 |

3 |

6 |

971 |

979 |

1050 |

28 |

33 |

|||||||

|

40 |

1000 |

1016.0 |

1021.0 |

+3.0 |

1235 |

40 |

74 |

1110 |

3 |

6 |

1073 |

+3.5 |

1081 |

+3.5 |

1160 |

28 |

39 |

|||||

|

44 |

1100 |

1117.6 |

1123.0 |

1345 |

42 |

78 |

1220 |

3 |

8 |

1175 |

1185 |

1270 |

28 |

39 |

||||||||

|

48 |

1200 |

1219.2 |

1224.0 |

1465 |

44 |

82 |

1325 |

3 |

8 |

1278 |

1290 |

1380 |

±1.5 |

32 |

39 |

|||||||

|

54 |

1350 |

1371.6 |

1377.0 |

1630 |

+3.0 |

48 |

88 |

1480 |

3 |

8 |

1432 |

1450 |

1540 |

36 |

45 |

|||||||

|

60 |

1500 |

1524.0 |

1529.0 |

1795 |

50 |

90 |

1635 |

3 |

8 |

1585 |

1600 |

1700 |

40 |

45 |

||||||||

JIS 16K Plate Flange Dimensions

|

Pipe |

Pipe |

Bo |

D |

t |

T |

G |

f |

r |

H |

X |

C |

Holes |

Bolt Dia. |

|||||||||

|

inch |

mm |

|||||||||||||||||||||

|

3/8 |

10 |

17.3 |

17.8 |

+0.5 |

90 |

+1.0 |

12 |

+1.0 |

16 |

±1.0 |

48 |

±0.8 |

1 |

4 |

26 |

+1.0 |

28 |

+1.0 |

65 |

±0.5 |

4 |

15 |

|

1/2 |

15 |

21.7 |

22.2 |

95 |

12 |

16 |

52 |

1 |

4 |

30 |

32 |

70 |

4 |

15 |

||||||||

|

3/4 |

20 |

27.2 |

27.7 |

100 |

14 |

20 |

58 |

1 |

4 |

38 |

42 |

75 |

4 |

15 |

||||||||

|

1 |

25 |

34.0 |

34.5 |

125 |

14 |

20 |

70 |

1 |

4 |

46 |

50 |

90 |

4 |

19 |

||||||||

|

1-1/4 |

32 |

42.7 |

43.2 |

135 |

16 |

22 |

80 |

2 |

5 |

56 |

60 |

100 |

4 |

19 |

||||||||

|

1-1/2 |

40 |

48.6 |

49.1 |

140 |

16 |

24 |

85 |

2 |

5 |

62 |

66 |

105 |

4 |

19 |

||||||||

|

2 |

50 |

60.5 |

61.1 |

155 |

16 |

24 |

100 |

2 |

5 |

76 |

80 |

120 |

8 |

19 |

||||||||

|

2-1/2 |

65 |

76.3 |

77.1 |

175 |

18 |

26 |

120 |

2 |

5 |

94 |

98 |

140 |

8 |

19 |

||||||||

|

3 |

80 |

89.1 |

90.0 |

200 |

20 |

28 |

135 |

2 |

6 |

108 |

112 |

160 |

8 |

23 |

||||||||

|

3-1/2 |

90 |

101.6 |

102.6 |

+1.0 |

210 |

20 |

30 |

145 |

2 |

6 |

120 |

124 |

170 |

8 |

23 |

|||||||

|

4 |

100 |

114.3 |

115.4 |

225 |

22 |

+1.5 |

34 |

160 |

2 |

6 |

134 |

138 |

185 |

8 |

23 |

|||||||

|

5 |

125 |

139.8 |

141.2 |

270 |

22 |

34 |

195 |

2 |

6 |

164 |

170 |

225 |

8 |

25 |

||||||||

|

6 |

150 |

165.2 |

166.6 |

305 |

+1.5 |

24 |

38 |

230 |

±0.9 |

2 |

6 |

196 |

202 |

260 |

±0.6 |

12 |

25 |

|||||

|

7 |

175 |

190.7 |

192.1 |

325 |

26 |

40 |

250 |

2 |

6 |

216 |

222 |

+1.5 |

280 |

12 |

25 |

|||||||

|

8 |

200 |

216.3 |

218.0 |

350 |

26 |

40 |

275 |

2 |

6 |

244 |

+1.5 |

252 |

305 |

12 |

25 |

|||||||

|

9 |

225 |

241.8 |

243.7 |

385 |

26 |

40 |

325 |

2 |

6 |

266 |

272 |

335 |

12 |

27 |

||||||||

|

10 |

250 |

267.4 |

269.5 |

430 |

28 |

44 |

345 |

2 |

6 |

304 |

312 |

380 |

12 |

27 |

||||||||

|

12 |

300 |

318.5 |

321.0 |

480 |

30 |

48 |

395 |

3 |

8 |

354 |

364 |

430 |

16 |

27 |

||||||||

|

14 |

350 |

355.6 |

358.1 |

540 |

34 |

52 |

±1.5 |

440 |

3 |

8 |

398 |

408 |

480 |

16 |

33 |

|||||||

|

16 |

400 |

406.4 |

409.0 |

+1.5 |

605 |

+2.0 |

38 |

60 |

495 |

3 |

10 |

446 |

456 |

+2.0 |

540 |

16 |

33 |

|||||

|

18 |

450 |

457.2 |

460.0 |

675 |

40 |

64 |

560 |

3 |

10 |

504 |

+2.0 |

514 |

605 |

±0.8 |

20 |

33 |

||||||

|

20 |

500 |

508.0 |

511.0 |

730 |

42 |

68 |

615 |

3 |

10 |

558 |

568 |

660 |

20 |

33 |

||||||||

|

22 |

550 |

558.8 |

562.0 |

795 |

44 |

70 |

670 |

±1.0 |

3 |

10 |

612 |

622 |

720 |

20 |

39 |

|||||||

|

24 |

600 |

609.6 |

613.0 |

+2.0 |

845 |

46 |

74 |

720 |

3 |

10 |

666 |

+2.5 |

676 |

+2.5 |

770 |

24 |

39 |

|||||

|

26 |

650 |

660.4 |

664.0 |

895 |

48 |

77 |

770 |

5 |

10 |

704 |

726 |

820 |

24 |

39 |

||||||||

|

28 |

700 |

711.2 |

715.0 |

960 |

50 |

80 |

820 |

5 |

10 |

754 |

776 |

875 |

24 |

42 |

||||||||

|

30 |

750 |

762.0 |

766.0 |

1020 |

+2.5 |

52 |

+2.0 |

83 |

880 |

5 |

10 |

806 |

832 |

935 |

24 |

42 |

||||||

|

32 |

800 |

812.8 |

817.0 |

+2.5 |

1085 |

54 |

86 |

930 |

5 |

10 |

865 |

+3.0 |

885 |

+3.0 |

990 |

±1.0 |

24 |

48 |

||||

|

34 |

850 |

863.6 |

868.0 |

1135 |

56 |

89 |

980 |

5 |

10 |

916 |

936 |

1040 |

24 |

48 |

||||||||

|

36 |

900 |

914.4 |

919.0 |

1185 |

58 |

93 |

1030 |

±1.2 |

5 |

10 |

968 |

986 |

1090 |

28 |

48 |

|||||||

|

40 |

1000 |

1016.0 |

1021.0 |

+3.0 |

1320 |

62 |

99 |

1140 |

5 |

12 |

1070 |

+3.5 |

1098 |

+3.5 |

1210 |

28 |

56 |

|||||

|

44 |

1100 |

1117.6 |

1123.0 |

1420 |

66 |

105 |

±2.0 |

1240 |

5 |

12 |

1180 |

1200 |

1310 |

32 |

56 |

|||||||

|

48 |

1200 |

1219.2 |

1225.0 |

1530 |

+3.0 |

70 |

112 |

1350 |

5 |

12 |

1282 |

1302 |

1420 |

±1.5 |

32 |

56 |

||||||

|

52 |

1300 |

1320.8 |

1326.0 |

1645 |

74 |

1450 |

5 |

1530 |

32 |

62 |

||||||||||||

|

54 |

1350 |

1371.6 |

1377.0 |

1700 |

76 |

1510 |

5 |

1590 |

32 |

62 |

||||||||||||

|

56 |

1400 |

1422.4 |

1428.0 |

1755 |

78 |

1560 |

5 |

1640 |

36 |

62 |

||||||||||||

|

60 |

1500 |

1524.0 |

1529.0 |

1865 |

80 |

1670 |

5 |

1750 |

36 |

62 |

||||||||||||

JIS 20K Plate Flange Dimensions

|

Pipe |

Pipe |

Bo |

D |

t |

T |

G |

f |

r |

H |

X |

C |

Holes |

Bolt Dia. |

|||||||||

|

inch |

mm |

|||||||||||||||||||||

|

3/8 |

10 |

17.3 |

17.8 |

+0.5 |

90 |

+1.0 |

14 |

+1.0 |

20 |

±1.0 |

48 |

±0.8 |

1 |

4 |

30 |

+1.0 |

32 |

+1.0 |

65 |

±0.5 |

4 |

15 |

|

1/2 |

15 |

21.7 |

22.2 |

95 |

14 |

20 |

52 |

1 |

4 |

34 |

36 |

70 |

4 |

15 |

||||||||

|

3/4 |

20 |

27.2 |

27.7 |

100 |

16 |

22 |

58 |

1 |

4 |

40 |

42 |

75 |

4 |

15 |

||||||||

|

1 |

25 |

34.0 |

34.5 |

125 |

16 |

24 |

70 |

1 |

4 |

48 |

50 |

90 |

4 |

19 |

||||||||

|

1-1/4 |

32 |

42.7 |

43.2 |

135 |

18 |

26 |

80 |

2 |

5 |

56 |

60 |

100 |

4 |

19 |

||||||||

|

1-1/2 |

40 |

48.6 |

49.1 |

140 |

18 |

26 |

85 |

2 |

5 |

62 |

66 |

105 |

4 |

19 |

||||||||

|

2 |

50 |

60.5 |

61.1 |

155 |

18 |

26 |

100 |

2 |

5 |

76 |

80 |

120 |

8 |

19 |

||||||||

|

2-1/2 |

65 |

76.3 |

77.1 |

175 |

20 |

30 |

120 |

2 |

5 |

100 |

104 |

140 |

8 |

19 |

||||||||

|

3 |

80 |

89.1 |

90.0 |

200 |

22 |

+1.5 |

34 |

135 |

2 |

6 |

113 |

117 |

160 |

8 |

23 |

|||||||

|

3-1/2 |

90 |

101.6 |

102.6 |

+1.0 |

210 |

24 |

36 |

145 |

2 |

6 |

126 |

130 |

170 |

8 |

23 |

|||||||

|

4 |

100 |

114.3 |

115.4 |

225 |

24 |

36 |

160 |

2 |

6 |

138 |

142 |

185 |

8 |

23 |

||||||||

|

5 |

125 |

139.8 |

141.2 |

270 |

26 |

40 |

195 |

2 |

6 |

166 |

172 |

225 |

8 |

25 |

||||||||

|

6 |

150 |

165.2 |

166.6 |

305 |

+1.5 |

28 |

42 |

230 |

±0.9 |

2 |

6 |

196 |

202 |

260 |

±0.6 |

12 |

25 |

|||||

|

7 |

175 |

190.7 |

192.1 |

325 |

30 |

46 |

250 |

2 |

6 |

218 |

226 |

+1.5 |

280 |

12 |

25 |

|||||||

|

8 |

200 |

216.3 |

218.0 |

350 |

30 |

46 |

275 |

2 |

6 |

244 |

+1.5 |

252 |

305 |

12 |

25 |

|||||||

|

9 |

225 |

241.8 |

243.7 |

385 |

32 |

48 |

300 |

2 |

6 |

266 |

274 |

335 |

12 |

27 |

||||||||

|

10 |

250 |

267.4 |

269.5 |

430 |

34 |

52 |

±1.5 |

345 |

2 |

6 |

304 |

312 |

380 |

12 |

27 |

|||||||

|

12 |

300 |

318.5 |

321.0 |

480 |

36 |

56 |

395 |

3 |

8 |

354 |

364 |

430 |

16 |

27 |

||||||||

|

14 |

350 |

355.6 |

358.1 |

540 |

40 |

62 |

440 |

3 |

8 |

398 |

408 |

480 |

16 |

33 |

||||||||

|

16 |

400 |

406.4 |

409.0 |

+1.5 |

605 |

+2.0 |

46 |

70 |

495 |

3 |

10 |

446 |

456 |

+2.0 |

540 |

16 |

33 |

|||||

|

18 |

450 |

457.2 |

460.0 |

675 |

48 |

78 |

560 |

3 |

10 |

504 |

+2.0 |

514 |

605 |

±0.8 |

20 |

33 |

||||||

|

20 |

500 |

508.0 |

511.0 |

730 |

50 |

84 |

615 |

3 |

10 |

558 |

568 |

660 |

20 |

33 |

||||||||

|

22 |

550 |

558.8 |

562.0 |

795 |

52 |

+2.0 |

90 |

670 |

±1.0 |

3 |

10 |

612 |

622 |

720 |

20 |

39 |

||||||

|

24 |

600 |

609.6 |

613.0 |

+2.0 |

845 |

54 |

96 |

720 |

3 |

10 |

666 |

+2.5 |

676 |

+2.5 |

770 |

24 |

39 |

|||||

|

26 |

650 |

660.4 |

664.0 |

945 |

60 |

790 |

5 |

850 |

24 |

48 |

||||||||||||

|

28 |

700 |

711.2 |

715.0 |

995 |

64 |

840 |

5 |

900 |

24 |

48 |

||||||||||||

|

30 |

750 |

762.0 |

766.0 |

1080 |

+2.5 |

68 |

900 |

5 |

970 |

±1.0 |

24 |

56 |

||||||||||

|

32 |

800 |

812.8 |

817.0 |

+2.5 |

1140 |

72 |

960 |

5 |

1030 |

24 |

56 |

|||||||||||

|

34 |

850 |

863.6 |

868.0 |

1200 |

74 |

1020 |

±1.2 |

5 |

1090 |

24 |

56 |

|||||||||||

|

36 |

900 |

914.4 |

919.0 |

1250 |

76 |

1070 |

5 |

1140 |

28 |

56 |

||||||||||||

PN16 Plate Flange Dimension

| Bore | Common Dimension | Raised Face | Drilling | Approx. Weight (Kg) |

|||||||

| Nominal Bore | d1 | D | t | K | d4 | f | Number of Bolts | x | d2 | DIN 2543 | |

| 10 |

14

|

90 | 14 | 60 | 40 | 2 | 4 | M12 | (1/2") | 14 | 0.63 |

|

17.2*

|

|||||||||||

| 15 |

20

|

95 | 14 | 65 | 45 | 2 | 4 | M12 | (1/2") | 14 | 0.72 |

|

21.3*

|

|||||||||||

| 20 |

25

|

105 | 16 | 75 | 58 | 2 | 4 | M12 | (1/2") | 14 | 1.01 |

|

26.9*

|

|||||||||||

| 25 |

30

|

115 | 16 | 85 | 68 | 2 | 4 | M12 | (1/2") | 14 | 1.23 |

|

33.7*

|

|||||||||||

| 32 |

38

|

140 | 16 | 100 | 78 | 2 | 4 | M16 | (5/8") | 18 | 1.80 |

|

42.4*

|

|||||||||||

| 40 |

44.5

|

150 | 16 | 110 | 88 | 3 | 4 | M16 | (5/8") | 18 | 2.09 |

|

48.3*

|

|||||||||||

| 50 |

57

|

165 | 18 | 125 | 102 | 3 | 4 | M16 | (5/8") | 18 | 2.88 |

|

60.3*

|

|||||||||||

| 65 |

76.1*

|

185 | 18 | 145 | 122 | 3 | 4 | M16 | (5/8") | 18 | 3.66 |

| 80 |

88.9

|

200 | 20 | 160 | 138 | 3 | 8 | M16 | (5/8") | 18 | 4.77 |

| 100 |

108

|

220 | 20 | 180 | 158 | 3 | 8 | M16 | (5/8") | 18 | 5.65 |

|

114.3*

|

|||||||||||

| 125 |

133

|

250 | 22 | 210 | 188 | 3 | 8 | M16 | (5/8") | 18 | 8.42 |

|

139.7*

|

|||||||||||

| 150 |

159

|

285 | 22 | 240 | 212 | 3 | 8 | M20 | (3/4") | 23 | 10.4 |

|

168.3*

|

|||||||||||

| 200 |

216

|

340 | 24 | 295 | 268 | 3 | 12 | M20 | (3/4") | 23 | 16.1 |

|

219.1*

|

|||||||||||

| 250 |

267

|

405 | 26 | 355 | 320 | 3 | 12 | M24 | (7/8") | 27 | 24.9 |

|

273*

|

|||||||||||

| 300 |

318

|

460 | 28 | 410 | 378 | 4 | 12 | M24 | (7/8") | 27 | 35.1 |

|

323.9*

|

|||||||||||

| 350 |

355.6*

|

520 | 30 | 470 | 438 | 4 | 16 | M24 | (7/8") | 27 | 47.8 |

|

368

|

|||||||||||

| 400 |

406.4*

|

580 | 32 | 525 | 490 | 4 | 16 | M27 | (1") | 30 | 63.5 |

|

419

|

|||||||||||

| 500 |

508*

|

715 | 36 | 650 | 610 | 4 | 20 | M30 | (1-1/8") | 33 | 102.0 |

ANSI B16.5 Plate Flanges Pressure Ratings

| Flanges pressure rating in psig for Plate

Flange ASME |

|||||||

| Temperature (F°) | 150# | 300# | 400# | 600# | 900# | 1500# | 2500# |

| -20 to 100 | 285 | 740 | 985 | 1480 | 2220 | 3705 | 6170 |

| 200 | 260 | 680 | 905 | 1360 | 2035 | 3395 | 5655 |

| 300 | 230 | 655 | 870 | 1310 | 1965 | 3270 | 5450 |

| 400 | 200 | 635 | 845 | 1265 | 1900 | 3170 | 5280 |

| 500 | 170 | 605 | 805 | 1205 | 1810 | 3015 | 5025 |

| 600 | 140 | 570 | 755 | 1135 | 1705 | 2840 | 4730 |

| 650 | 125 | 550 | 730 | 1100 | 1650 | 2745 | 4575 |

| 700 | 110 | 530 | 710 | 1060 | 1590 | 2655 | 4425 |

| 750 | 95 | 505 | 675 | 1015 | 1520 | 2535 | 4230 |

| 800 | 80 | 410 | 550 | 825 | 1235 | 2055 | 3430 |

| 850 | 65 | 320 | 425 | 640 | 955 | 1595 | 2655 |

| 900 | 50 | 230 | 305 | 460 | 690 | 1150 | 1915 |

| 950 | 35 | 135 | 185 | 275 | 410 | 685 | 1145 |

| 1000 | 20 | 85 | 115 | 170 | 255 | 430 | 715 |