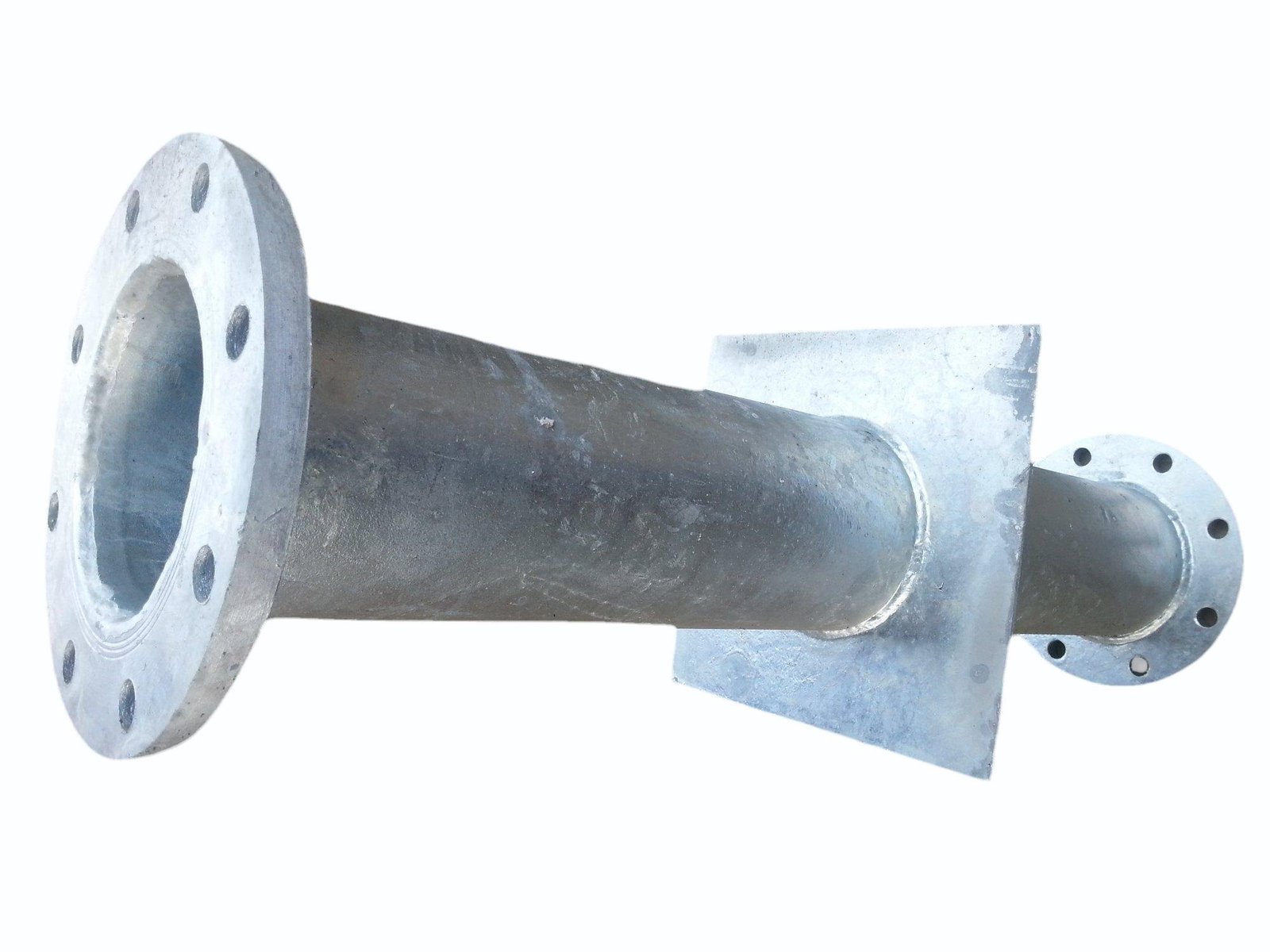

GI (Galvanized Iron) puddle flanges are widely used in industries requiring reliable water and gas-tight seals, particularly in applications such as water treatment plants, sewage systems, and construction projects. Repute Steel & Engineering Co. is a reputable manufacturer, stockist, and exporter of high-quality GI puddle flanges, designed to provide a durable and leak-proof connection for piping systems that pass through walls, tanks, or other structures. The GI coating, a layer of zinc applied to the iron, offers exceptional resistance to corrosion, ensuring the long-term durability of the flange in various industrial environments.

As a manufacturer, Repute Steel & Engineering Co. produces GI puddle flanges to meet stringent industry standards, with precision engineering that ensures the flanges are of superior quality. The company offers a wide range of sizes and configurations, customized to fit the specific requirements of their clients. Whether it's for a small-scale water pipeline or a large industrial project, the GI puddle flanges manufactured by Repute Steel & Engineering Co. are designed to withstand harsh environmental conditions, providing enhanced protection against rust and corrosion. Their galvanized finish not only prolongs the life of the product but also offers cost-effective solutions for long-lasting performance.

Repute Steel & Engineering Co. has established a strong export network, with its GI puddle flanges being shipped to key markets including Oman, Qatar, Saudi Arabia, the United Arab Emirates (UAE), Bahrain, and the United States. These regions benefit from the company’s consistent supply of high-quality products, which are used in a range of industries such as oil and gas, water treatment, construction, and infrastructure projects. With a focus on quality and reliability, Repute Steel & Engineering Co. has built lasting relationships with distributors and contractors in these countries, ensuring timely deliveries and comprehensive support for all their projects.

Specification of GI puddle flange

| Property | Specification |

|---|---|

| Material | Stainless Steel 304 |

| Grade | 304, 304L (Low Carbon Version) |

| Type of Flange | Weld Neck, Slip-On, Blind, Threaded, Socket Weld, Lap Joint |

| Standard | ASME B16.5, ASME B16.47, BS 4504, EN 1092-1 |

| Size Range | ½” (DN 15) to 24” (DN 600) |

| Pressure Rating | 150#, 300#, 600#, 900#, 1500# (according to ANSI B16.5) |

| Flange Thickness | 2mm to 70mm (depending on size and pressure rating) |

| Material Composition | - Carbon: 0.08% Max |

| - Manganese: 2.00% - 2.50% | |

| - Phosphorus: 0.045% Max | |

| - Sulfur: 0.030% Max | |

| - Chromium: 18.0% - 20.0% | |

| - Nickel: 8.0% - 10.5% | |

| Temperature Range | -196°C to 800°C (Maximum Service Temperature) |

| Finish | - Hot Rolled, Cold Rolled, Polished (Mirror, 2B, No.1, etc.) |

| Application | Chemical processing, oil & gas, food and beverage, power generation, construction, etc. |

| Testing | - Hydrostatic Test |

| - Visual Inspection | |

| - Dimensional Check | |

| - Ultrasonic Test (UT) or Radiography (RT) |

The company's success in the global market can be attributed to its commitment to providing premium-quality GI puddle flanges that meet the specific needs of diverse industries. With a strong emphasis on customer satisfaction, Repute Steel & Engineering Co. collaborates closely with clients to ensure that their products are tailored to meet the exact specifications of each project. Their experienced team of engineers and specialists offers expert advice and assistance, ensuring that every GI puddle flange is of the highest standard, both in terms of functionality and durability.

Repute Steel & Engineering Co.'s dedication to innovation and customer-centric solutions ensures that their GI puddle flanges continue to meet the evolving needs of industries worldwide. As a trusted supplier, the company has earned a reputation for reliability, quality, and excellent customer service, making it the preferred choice for contractors and distributors in markets across the Middle East and the United States.

Chemical Composition of GI puddle flange

| Material | Element | Percentage (%) |

|---|---|---|

| Mild Steel (Base Metal) | Carbon (C) | 0.12 - 0.25 |

| Manganese (Mn) | 0.30 - 0.60 | |

| Phosphorus (P) | ≤ 0.04 | |

| Sulfur (S) | ≤ 0.05 | |

| Silicon (Si) | 0.10 - 0.40 | |

| Iron (Fe) | Balance | |

| Galvanized Coating (Zinc) | Zinc (Zn) | 98 - 99% |

Mechanical Properties of GI puddle flange

| Material | Mechanical Property | Value |

|---|---|---|

| Mild Steel Base (Pre-Galvanized) | Yield Strength (YS) | 250 - 350 MPa |

| Ultimate Tensile Strength (UTS) | 400 - 500 MPa | |

| Elongation (%) | 20 - 25% | |

| Hardness (Rockwell B) | 85 - 95 HB | |

| Modulus of Elasticity (E) | 200 GPa | |

| Galvanized Coating | Zinc Coating Thickness | 50 - 100 µm |

| Bond Strength (Zinc to Steel) | High, typically 10 - 20 MPa | |

| Hardness of Zinc Coating (Vickers) | 60 - 100 HV |

Countries we have exported our products to

manufacturer stockist and exporter of GI puddle flange in mumbai,manufacturer stockist and exporter of GI puddle flange in India,manufacturer stockist and exporter of GI puddle flange in United Arab Emirates,manufacturer stockist and exporter of GI puddle flange in Saudi Arabia,manufacturer stockist and exporter of GI puddle flange in Kuwait,manufacturer stockist and exporter of GI puddle flange in Bahrain Qatar,manufacturer stockist and exporter of GI puddle flange in Oman, manufacturer stockist and exporter of GI puddle flange in USATurkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands.

Countries we have exported our products to

Turkey, Thailand, Bulgaria, Serbia, Mexico, Estonia, Trinidad & Tobago,Tunisia, New Zealand, Indonesia, Puerto Rico, Ireland, India, Morocco, Brazil, Lebanon, Hong Kong, Jordan, Ukraine, Switzerland, Czech Republic, Lithuania, Sri Lanka, Greece, Taiwan, Zimbabwe, Algeria, Romania, Mexico, Ghana, Italy, Philippines, Spain, United Kingdom, Finland, Azerbaijan, Japan, Macau, Israel, Saudi Arabia, Kenya, Bhutan, Poland, Poland, Costa Rica, Kuwait, Singapore, Pakistan, France, Colombia, Tibet, Bolivia, Portugal, Iraq, Australia, Kazakhstan, Nepal, Mongolia, Gambia, Malaysia, Chile, Germany, Slovakia, China, Bahrain, Denmark, Angola, Afghanistan, Peru, Austria, Ecuador, Gabon, Croatia, South Africa, Sweden, Chile, Hungary, United Arab Emirates, Argentina, Bangladesh, Oman, Egypt, United States, Belgium, Canada, Namibia, Norway, Qatar, Belarus, Netherlands,manufacturer stockist and exporter of GI puddle flange in Bengaluru,manufacturer stockist and exporter of GI puddle flange in Chennai,manufacturer stockist and exporter of GI puddle flange in Hyderabad,manufacturer stockist and exporter of GI puddle flange in Gujarat,manufacturer stockist and exporter of GI puddle flange in Pune